A new nanostructure called Graphene Nanomesh opens up a band gap

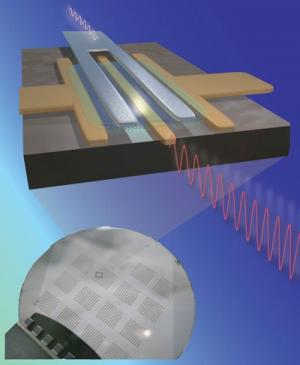

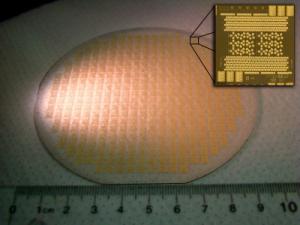

Researchers from UCLA has created a new Graphene nanostructure called Graphene nanomesh (GNM). The new structure is able to open up a band gap in a large sheet of graphene to create a highly uniform, continuous semiconducting thin film that may be processed using standard planar semiconductor processing methods.

The nanomesh can have variable periodicities, defined as the distance between the centers of two neighboring nanoholes. Neck widths, the shortest distance between the edges of two neighboring holes, can be as low as 5 nanometers. This ability to control nanomesh periodicity and neck width is very important for controlling electronic properties because charge transport properties are highly dependent on the width and the number of critical current pathways.