Graphene Oxide: A Hands-on Guide to Practical Applications

The following article was sent to us by Corey McCarren and Dr. Elena Polyakova from Graphene Laboratories (a Graphene-Info sponsor), discussing Graphene Oxide and its applications:

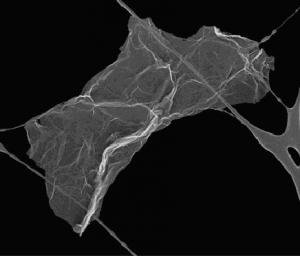

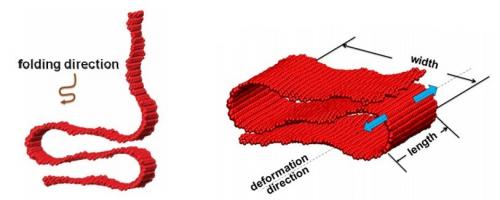

Graphene, a multi or single layer sheet of graphite, is considered a key material in producing the next generation of low-cost carbon-based transparent and flexible electronics. Graphene is the strongest material available, as well as being highly transparent, flexible, and the best conductor of heat and electricity. Great effort is devoted to developing an effective yet inexpensive way to produce graphene materials in industrial quantities.