Graphene ribbons and car paint used to make an excellent radar ice protecting coating

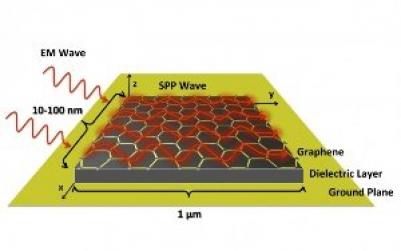

Researchers from Rice University in collaboration with Lockheed Martin developed a new graphene based compound that can be used as a deicing (ice protection) coating for marine and airborne radars.

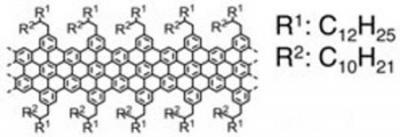

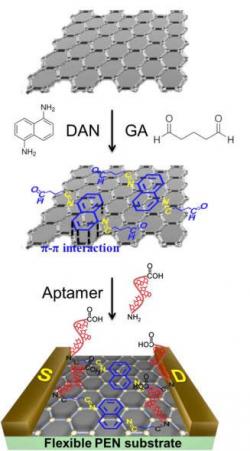

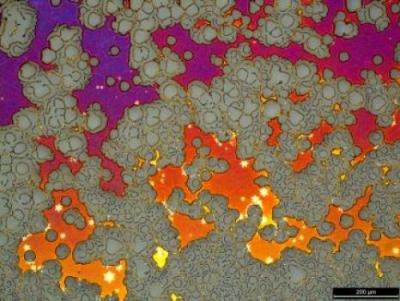

Currently most radar domes use ceramic alumina for deicing, but it takes a lot of power to heat them if they are coated with ice because they are poor conductors. The new compound is based on graphene nano-ribbons (GNRs) and polyurethane car paint. The car paint helps the graphene stay on the radar dome.