What is a foam?

A foam is a substance in which gas is trapped in a liquid or a solid in pockets. There are many types of foams - for example, those used by firefighters (mostly to combat burning oils). A bread is also, at least formally, a type of foam.

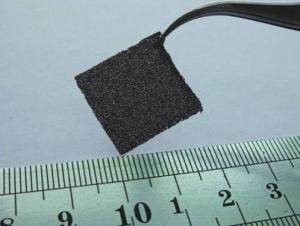

Graphene Foams

Graphene foams are usually made by growing graphene using a CVD process on a 3D metal foam (structure). The metal is then removed which leaves the graphene 3D foam.

A graphene foam is strong and conductive and useful for many applications - sensors, purification/absorption materials - and more.

Graphene foams are somewhat similar to graphene aerogels, in which the liquid part of the gel is replaced by a gas (usually air).

Graphene foams are now available commercially, contact us for details.