KAUST researchers have found that a layer of hierarchically three-dimensional porous graphene can greatly suppress polysulfide shuttling - a problem known to be holding back the development of lithium-sulfur batteries. This could potentially help create high-density batteries that are useful for various applications, like electric vehicles and more.

Li-S batteries have several potential advantages over the most commonly used types of batteries. They have a higher theoretical energy storage capacity and sulfur is a nontoxic element readily available in nature. Sulfur is also a waste product of the petrochemical industry, so it could be obtained relatively cheaply while increasing the sustainability of another industry.

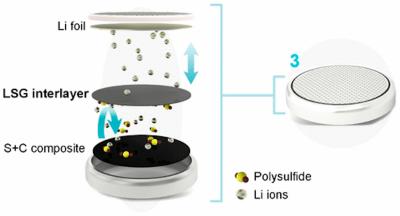

The KAUST team’s solution is based on a layer of graphene. They make this by subjecting a polyimide polymer to laser energy in a process called laser scribing, creating a suitably structured porous material. A key feature is that the material is hierarchically porous in three dimensions, meaning it has an array of pores of different sizes. Nano-sized carbon particles are then added and taken up by the pores to form the final product.

Eman Alhajji, Ph.D. student and first author of the research paper, worked with KAUST colleagues and found that placing a thin layer of this material between the cathode and anode of an Li-S battery significantly suppresses the polysulfide shuttling.

Making this freestanding interlayer just a few micrometers thick was a challenge, says Alhajji, adding, It was fun to roll it like playdough, but then I had to handle it in a very gentle manner, especially during battery assembly.

Until now, most options proposed to solve the polysulfide shuttling problem have suffered from limitations that make them unsuitable for large-scale commercial application. In contrast, the laser-scribed graphene developed at KAUST is produced by a method that the researchers describe as scalable and straightforward.