Scientists from the Institute of Physical Chemistry of the Polish Academy of Sciences in Warsaw and Fuzhou University in China developed an innovative photocatalytic material from zinc oxide nanorod arrays grown on a graphene substrate and "decorated" with dots of cadmium sulphide. In the presence of solar radiation, the material showed to be a great catalyst for chemical reactions.

The material adheres to the principles to photocatalytics, in which radiation (both visible and ultraviolet) is used to activate chemical compounds and carry out reactions which store solar energy. This newly created photocatalyst operates quite simply; when a photon with the appropriate energy meets the semiconductor, an electron-hole pair forms. Under normal circumstances it would almost immediately recombine and the solar energy would be lost. However, in the new material electrons - released in both semiconductors as a result of interaction with the photons - quickly flow down along the nanorods to the graphene base, which is an excellent conductor. Recombination can not occur and the electrons can be used to create new chemical bonds and thus to synthesize new compounds. The actual chemical reaction takes place on the surface of the graphene, previously coated with the organic compounds which are to be processed.

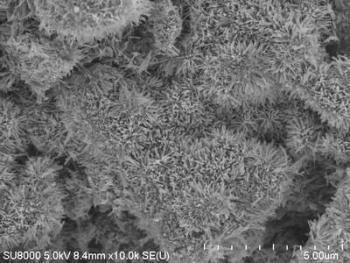

The researchers state that he material operates with a high yield. After exposure to solar radiation within no more than half an hour it processed 80% and sometimes even more than 90% of the substrates. Furthermore, its great advantage is the ease of its production. Graphene suitable for applications in photochemistry is now available without any greater problems and is not expensive. In turn, the invented process of coating graphene with plantations of zinc oxide nanorods, on which cadmium sulphide is subsequently deposited, is fast, efficient, takes place at a temperature just slightly higher than room temperature, at normal pressure, and does not require any sophisticated substrates. It is also important, for application on a broader scale, that the new photocatalyst is consumed slowly. The experiments carried out to date show that only after the sixth-seventh use does a slight decrease of about 10% in the yield of the reaction occur. Skillfully used, the new 3D photocatalyst may significantly alter the course of chemical reactions. Its use, e.g. in the pharmaceutical industry, could reduce the number of stages of production of certain pharmacological compounds from a dozen to just a few.

Source: nanowerk