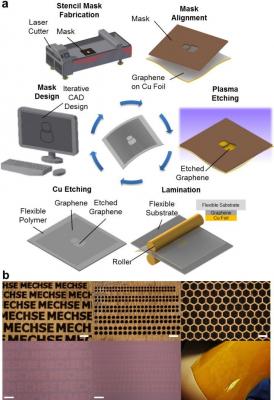

Researchers from the University of Illinois at Urbana-Champaign have developed a one-step method to pattern graphene by using stencil mask and oxygen plasma reactive-ion etching, and subsequent polymer-free direct transfer to flexible substrates.

The researchers explain that despite progress made in the direct synthesis of large-area, uniform, high quality graphene films using chemical vapor deposition (CVD) with various precursors and catalyst substrates, the infrastructure requirements on post-synthesis processing, patterning and transfer for creating interconnects, transistor channels, or device terminals have slowed the implementation of graphene in a wider range of applications. This simple and scalable graphene patterning technique is based on a shadow mask technique that has been employed for contact metal deposition; Not only are these stencil masks easily and rapidly manufactured for iterative rapid prototyping, they are also reusable, enabling cost-effective pattern replication. Since this approach involves neither a polymeric transfer layer nor organic solvents, it can obtain contamination-free graphene patterns directly on various flexible substrates.

The scientists stated that this approach demonstrates a new possibility to overcome limitations imposed by existing post-synthesis processes to achieve graphene micro-patterning. They envision this facile approach to graphene patterning holds promise for transformative changes in "do It yourself" (DIY) graphene-based device development for broad applications including flexible circuits/devices and wearable electronics.