Researchers from Pohang University of Science and Technology (POSTECH), Korea Institute of Industrial Technology and Konkuk University have fabricated highly deformable graphene-based micro supercapacitors (MSCs) using liquid metal current collectors on an elastic polymer substrate.

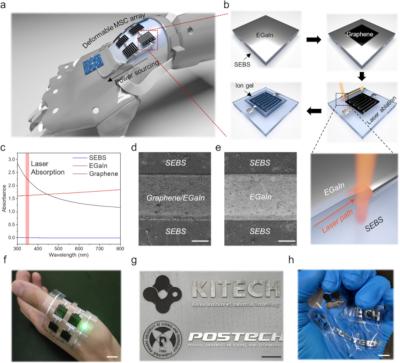

a Illustration of an integrated system comprising soft-electronics and deformable energy storage component. b The fabrication process of EGaIn-based MSC. c UV-vis spectra of SEBS, EGaIn, and graphene. FE-SEM images of laser ablated d Graphene/EGaIn and e EGaIn (Scale bar = 200 µm). Photographs of f institute logos, g deformed logos, and h an LED connected to the MSC circuit (Scale bar = 1 cm). (Image from npj Flexible Electronics)

The team used eutectic gallium-indium (EGaIn), a liquid metal alloy, as the current collector since a deformable current collector is needed in order to create a deformable MSC. Commonly used current collectors made of brittle materials like gold (Au) are not suitable in this case, so the team turned to 'liquid metal' that inherently possesses the properties of a liquid and metallic conductivity.

The fabrication process began with coating a thin film of EGaIn onto a stretchable styrene-ethylene-butylene-styrene (SEBS) substrate, followed by the deposition of a graphene layer to serve as the active electrode material. The researchers selectively ablated graphene and EGaIn to obtain interdigitated pattern by using laser, exploiting the strong laser absorption of these materials compared to the transparent SEBS. By carefully tuning the laser intensity, they achieved precise patterning without damaging the underlying elastic substrate.

The choice of materials proved crucial to the success of this approach. The scientists explained that they successfully achieved patterning of the liquid metal by utilizing its excellent absorption of the laser's wavelength. Adjusting the intensity of the laser enabled them to prevent the damage to the substrate caused by the heat induced by laser, whereas both the graphene and liquid metal were ablated by the laser.

The SEBS substrate, which does not absorb the laser wavelength, can withstand the heat generated during ablation, allowing for the creation of high-resolution patterns with electrode gaps as small as 90 µm.

The resulting MSCs exhibited impressive performance, achieving areal capacitances up to 1336 µF cm-2 while maintaining good rate capability. Importantly, the devices showed no significant degradation under various mechanical deformations, including folding, wrinkling, twisting, and stretching, even after 1000 deformation cycles.

To demonstrate the practical potential of their MSCs, the researchers integrated an array of devices with light-emitting diodes to create a stretchable lighting system. The system maintained stable operation under severe bending, twisting, and stretching, showcasing the MSCs' ability to reliably power deformable electronics.

Looking ahead, the team will seek further improvement and envisions exciting possibilities for future applications. While additional work is needed to enhance the mechanical durability of the gel electrolyte used in these MSCs, the use of laser-patterned liquid metal electrodes represents a significant step forward in the development of truly deformable energy storage solutions.