This is a sponsored post by SP Nano

Israel-based SP Nano developed a unique dispersion technology based on a genetically engineered exceptionally stable protein that is highly suitable for carbon nanoparticles (CNPs) dispersion, including graphene, CNTs and carbon black.

Following years of intensive R&D, SP Nano is now offering its dispersions to application developers. This is the first time that carbon nanomaterials can “truly” be dispersed and achieve cutting-edge performance across a wide range of applications.

SP Nano’s dispersions are now being applied to a wide range of applications, such as

- Coatings (textiles, surfaces, powders, etc.)

- Dispersions in matrices (resins, polymers, etc.)

- Liquid formulations (coolants, inks, slurries, etc.)

The unequalled dispersion technology unleashes the huge potential of carbon nanoparticles in applications that require excellent properties, such as thermal and electrical conductance, wear resistance and other mechanical properties. Applications such as batteries, supercapacitors, thermal interface materials, coolants, electrically conductive textiles, conductive inks, cosmetics, tissue engineering, coatings, adhesives, composites, paints, smart textiles, etc.

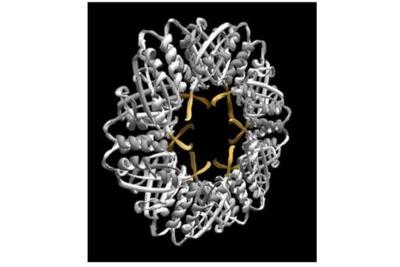

About the SP1 protein

SP1 is a boiling stable protein, originally isolated from the Aspen tree. It is also resistant to detergents, organic solvents, and proteases, rendering it suitable for many industries and low cost to produce by industrial fermentation. SP Nano has genetically engineered the exceptionally stable SP1 protein and is commercializing it for specific tailored carbon nanoparticles solutions. The engineered SP1 presents 12 times on its surface a peptide specific for graphitic surfaces and therefore binds very tightly to graphene, CNT and other CNPs resulting in extremely stable water dispersions of high concentrations.

See image below for the SP1 crystal structure. The image shows the ring-like structure, where the yellow ribbons represent the graphitic binding peptide. The peptide enables the protein to dock with high avidity on carbon nanoparticles. The tight binding is derived by simultaneous binding by 6 peptides, while each peptide contains several binding sites. Once bound to the carbon nanoparticle, the protein will never release its binding.

The rest of the protein’s surface can be involved in many other desired interactions with polymers and small molecules of choice to adapt the SP1/CNP complex to different chemical environments.

From agglomerates to dispersions

The SP1 technology provides excellent dispersions of CNT and graphene without chemically modifying their surfaces (such modifications disrupt the molecular structure of CNPs and compromise their properties) or using surfactants (whose affinity to the CNPs is moderate and are thereforenecessary in large amounts,which interfere with downstream applications).

The main advantages of SP1-based dispersions:

- Higher dispersion level

- Higher stability

- Reduced viscosity

- Increased solid content

- Low SP1 to CNP ratio

- Stronger affinity

- Pristine CNP

- The dispersions are available in: Water, NMP, DMSO, DMF, Ethylene glycol, Glycerol, and resins

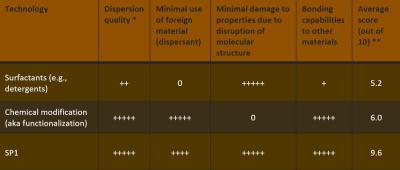

Comparison of SP1 with current state of the art dispersion methods

* The dispersion quality combines 3 parameters: separation level, stability, and sensitivity

** The grade for “Minimal damage to properties due to disruption of molecular structure” has a double weight in the weighted average calculation

The flexibility of SP Nano’s SP1 technology

SP1 technology has some exceptional properties that make it an excellent solution for the materials industry. In addition, to adapt and/or promote bonding of the SP1/CNP complex to any system/matrix/environment, the SP1 part of the SP1/CNP complex is an excellent platform for the inclusion of additional functional groups of choice:

- SP1 can be further programmed by genetic engineering to add new properties or to subtract existing ones

- SP1 can be chemically modified to have many optional chemical moieties

- The SP1/CNP complex can be further complexed with other particles or polymers (e.g., latex) to create a higher order complexes/structures as ternary, quaternary, or higher order complexes

Composite materials nano-reinforcement

One example of SP1’s advantages is in composite materials. SP1 enables two approaches for composites nano-reinforcement: Dispersion in resin, or fibers coating. SP1/CNP complex binds to fibers of textiles (including carbon, glass, aramid and more). The material can be dispersed in resins, adhesives, paints, binders and more. SP1/CNT improves inter-laminar mechanical properties:

- Enhancing fibers to resin bonding -> leading to efficient load transfer and shifting adhesive to cohesive failure

- Arresting crack propagation -> leading to an increased fracture toughness

- Overcoming delamination issues caused by adhesive failure -> thus enabling impossible fibers-matrix combinations

SP1 binds covalently to matrices such as epoxy, phenolic etc. SP1 comprises a variety of functional groups that facilitate a diverse chemistry with different resins. In epoxy or phenolic resins, the multitude of amine groups of SP1 create covalent bonds with the matrix, which together with the tight binding of the CNP itself, guaranteeing that the CNP will be torn and not pulled out, thereby serving as a true nano-reinforcement.

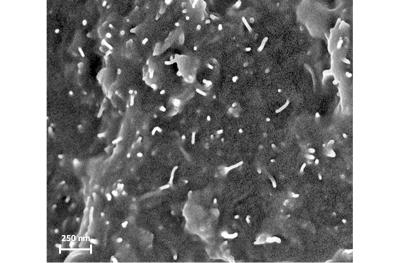

As can be seen in the image below, it is evident that the CNTs are homogeneously dispersed, and that all the CNTs are torn at the fracture surface, indicating that they were participating in the effort to prevent the crack propagation. While epoxy fracture surfaces are usually smooth, the rough surface in the image indicates that the crack propagation in the treated material was interrupted by the CNTs.

HR-SEM of fracture surface of epoxy reinforced with SP1/MWCNT after T-Peel.

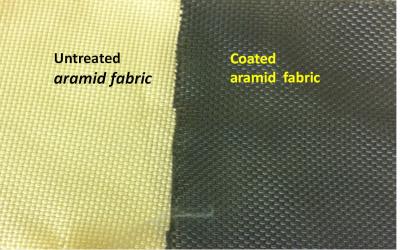

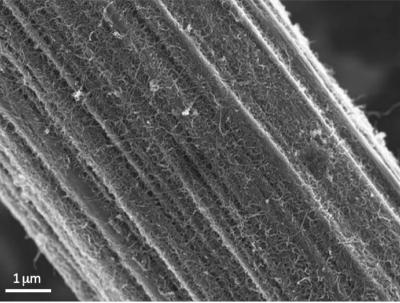

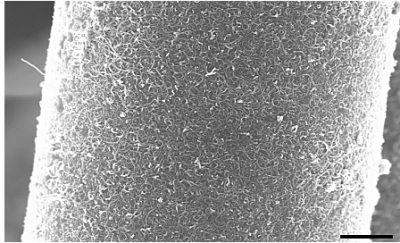

Surface coating

Another example of SP1’s technology advantages is with surface coating. SP1/CNP can be used to coat almost any surface of choice, including textiles using standard textile dyeing machines. Since carbon fibers have the same molecular configuration as graphene and CNT, these fibers are usually coated in one step: while the first set of 6 binding peptides of SP1 is bound to CNT or graphene, the second set of peptides on the other side of the ring-shaped protein tightly binds the carbon fibers.

Glass fabric coated with SP1/MWCNT

Kevlar coated with SP1/MWCNT

HR-SEM of a carbon fiber coated with SP1/MWCNT​

HR-SEM of a glass fiber coated with SP1/MWCNT

Applications in Steel

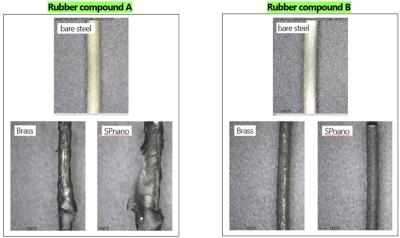

SP Nano technology serves also as an excellent adhesion promoter on steel wires (product developed together with one of the world largest steel wire manufacturers).

Pull out (ASTM D2229) of steel wire from rubber following their co-vulcanization is easy and no rubber is left bound to the wire. Traditionally, such alloys as brass must be used as coating for steel to promote adhesion to rubber during vulcanization. Coating of wires with SP1/CB/latex demonstrated equivalent excellent adhesion as can be seen below from the rubber coverage on the steel.

Summary

SP Nano developed an unequalled dispersion technology, based on a unique protein, that unleashes the huge potential of carbon nanoparticles in applications that require excellent properties, such as thermal and electrical conductance, wear resistance and other mechanical properties. Applications such as batteries, supercapacitors, thermal interface materials, coolants, , electrically conductive textiles, conductive inks, cosmetics, tissue engineering, coatings, adhesives, composites, paints, smart textiles, etc.

For more information, visit SP Nano’s home, or contact the team here.