AGM looks into graphene for aeroplanes, ships, vacuum cleaners, wind turbines and more

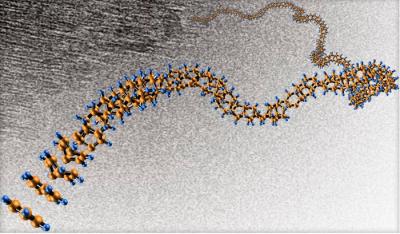

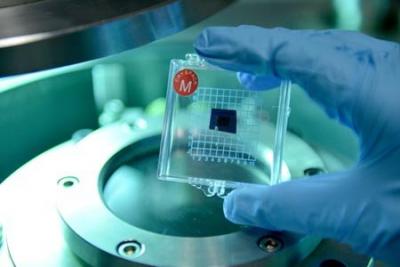

Bloomberg posted an interesting article on Applied Graphene Materials, the graphene maker that was established in 2010 as a spin-off from Durham University to develop a new CVD-based graphene synthesis method and produce graphene materials. The company's CEO, Jon MabbitT, details some interesting new applications they are trying to develop.

Bloomberg posted an interesting article on Applied Graphene Materials, the graphene maker that was established in 2010 as a spin-off from Durham University to develop a new CVD-based graphene synthesis method and produce graphene materials. The company's CEO, Jon MabbitT, details some interesting new applications they are trying to develop.

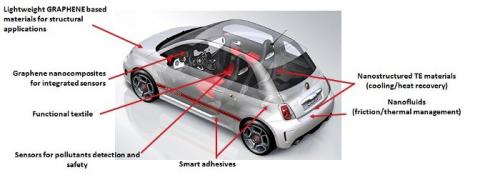

AGM is currently targeting two types of applications. First up are early-adopters, such as Formula 1 teams. But AGM is also looking to enter into long-term products - mainly in the aerospace industry. Graphene can enable stronger and lighter materials, suitable for aircraft. AGM is also working with Dyson (vacuum cleaner developer), Procter & Gamble, lubricants makers and wind-turbine developers. Finally, they are developing an impermeable rustproof coatings for ships.