Researchers report quantum anomalous Hall effect in rhombohedral graphene

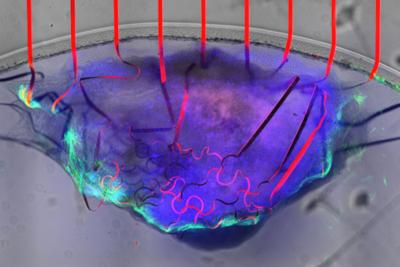

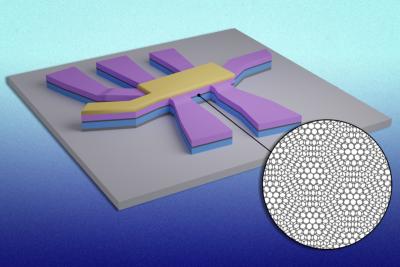

Researchers at the Massachusetts Institute of Technology (MIT), University of Texas at Dallas and Japan's National Institute for Materials Science have reported the quantum anomalous Hall effect (QAHE), a topological phenomenon that features quantized Hall resistance at zero magnetic field, in a rhombohedral pentalayer graphene-monolayer tungsten disulfide (WS2) heterostructure.

This achievement can also be described as a 'five-lane superhighway' for electrons, that could allow ultra-efficient electronics and more. The team explained that its discovery could have direct implications for low-power electronic devices because no energy is lost during the propagation of electrons, which is not the case in regular materials where the electrons are scattered.