Tata Steel has developed a new product, a few-layer film of rGO along with its collaborators at CeNS, Bengaluru. The company is now starting to mass-produce the films and offer them to application developers.

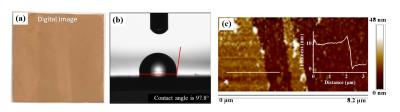

Figure 1: (a) Digital image of rGO/Cu foil (5 cm2). Contactact angle (b) and AFM height profile (c) on rGO/Cu

The rGO film is produced (using a modified CVD process) on copper. The film's average thickness is 5-10 nm and offers a corrosion rate of 0.02 mm/year (Tafel) and a water contact angle of ~ 97°.

These unique properties make the film suitable to protect the copper from corrosion, chemical attacks, and thermal oxidations. It also makes copper hydrophobic and can act as an antibacterial surface.

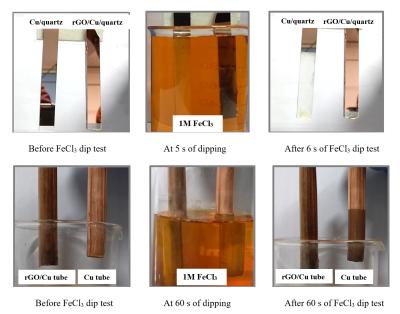

Figure 2: FeCl3 dip test was performed on rGO/Cu/quartz (top figure) and rGO/Cu tube (bottom figure) to show the versatility of coating on any arbitrary shape and substrates for protection against corrosion.

The film is also suitable for research applications. Tata Steel says that the functional groups (-OH) present on the surface make it an ideal substrate for studying biomolecules.

As this is a unique new material, there can be additional potential applications for its use.Tata Steel says it has already started reaching out to global customers and supply samples to leading companies in the EU, USA, and Asia.

The filmms are produced via a proprietary production process based on a modified CVD. The process involves a rotary vacuum with a substrate temperature of 750 °C. Tata can produce thousands of such films per month and can easily scale up its capacity. The process can be adapted to grow the film on curved surfaces. Tata Steel says it can also grow films on other materials such as Nickel, Steel, quartz using the same basic process. In fact, the films can be grown to any substrates stable till 750 °C. The rGO adhesion on Copper, Nickel, Steel, and quartz substrate is good. In particular, on a quartz substrate, the rGO film can withstand up to a 6H (Pencil hardness) hardness level.

After developing in-house graphene technologies for its own applications, Tata Steel established its graphene center in 2018. The Tata Steel Graphene Center researches and develops graphene materials and applications, and the company is now expanding its marketing reach globally.

Contact us at graphene.sales@tatasteel.com

This is a sponsored post by Tata Steel