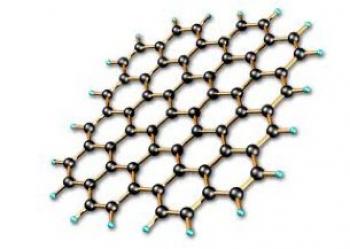

Grafoid to mass produce affordable high-quality graphene materials called MesoGraf

Grafoid sent us some very interesting news today as the company launched their graphene-based material platform called MesoGraf. They say that they will able to mass produce high-quality graphene at affordable prices. The National University of Singapore (NUS) launched new spin-off company called Graphite Zero which will handle the development and production of MesoGraf. Grafoid holds the majority stake in the new company, and will handle business development and marketing for the new material.

Grafoid says that they have managed to create a low-cost process that will enable them to mass produce graphene Mesograf materials. They say that their one-step chemical process is non-destructive and is environmentally sustainable.