Haydale acts to increase graphene inks manufacturing capability

Haydale announced a new 230 m2 dedicated manufacturing area at its South Wales, UK facility to keep up with rapidly growing demand for these ground breaking materials.

Haydale announced a new 230 m2 dedicated manufacturing area at its South Wales, UK facility to keep up with rapidly growing demand for these ground breaking materials.

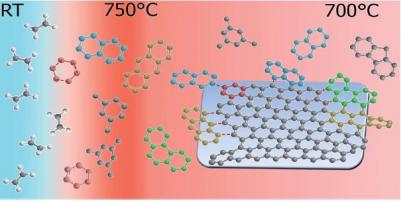

Haydale graphene inks are manufactured using plasma functionalised HDPlas® Graphene Nanoplatelets (GNPs) to deliver performance benefits including: metal-free, electrical conductivity, flexibility, and durability. Haydale graphene ink is formulated to be ready-to-use and can also be customized for individual applications. Their patented HDPlas® plasma process allows Haydale to use with a range of different raw graphene materials and to add the chemical functionalisation to meet desired performance for a wide range of specific applications.