Talga Resources to collaborate with German JenaBatteries on graphene-enhanced flow batteries

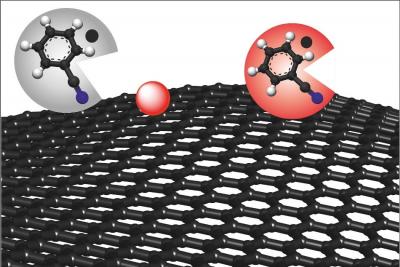

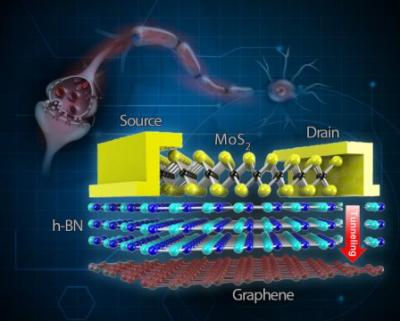

Talga Resources recently signed a collaboration agreement with JenaBatteries to jointly explore the use of Talga’s graphene products in flow batteries. Under the Agreement, Talga will formulate and supply graphene for testing in components producing JenaBatteries’ patented polymer flow battery, a type of redox flow battery suitable for commercial scale and grid applications.

Talga Resources recently signed a collaboration agreement with JenaBatteries to jointly explore the use of Talga’s graphene products in flow batteries. Under the Agreement, Talga will formulate and supply graphene for testing in components producing JenaBatteries’ patented polymer flow battery, a type of redox flow battery suitable for commercial scale and grid applications.

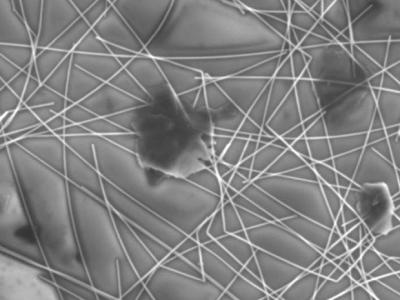

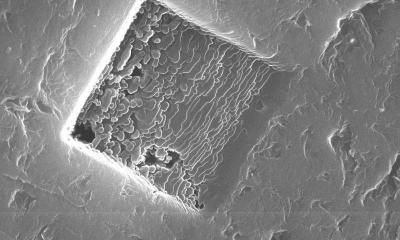

Talga’s graphene will aim to reduce manufacturing costs and increase the performance and longevity of the flow battery components by utilizing graphene’s properties of conductivity, chemical inertness and impermeability.