Talga Resources Ltd is a multi-national company focused on graphite mining and graphene supply and application development. The company mines graphite in Sweden, operates a test processing facility in Germany under Talga Advanced Materials GmbH and has a product development arm, Talga Technologies UK Ltd located in Cambridge, UK.

Talga Resources Ltd is a multi-national company focused on graphite mining and graphene supply and application development. The company mines graphite in Sweden, operates a test processing facility in Germany under Talga Advanced Materials GmbH and has a product development arm, Talga Technologies UK Ltd located in Cambridge, UK.

Talga is developing graphene products for additives to coatings, batteries, concrete and epoxy composites. Testing of Talga materials and products is underway with a range of corporations including industrial conglomerates Tata and BASF subsidiary Chemetall, UK listed Haydale, flexible battery maker Zinergy and German based Jena Batteries.

Talga Resources is a public company trading on the Australian Stock Exchange (ASX: TLG).

2 Richardson St

West Perth WA 6005

Australia

Talga successfully completes USD$27 million institutional placement

Talga Group has announced the completion of an institutional placement of A$40 million (around USD$27,316,000) from the issue of 25.8 million new fully paid ordinary Talga shares. The oversubscribed Placement, managed by Euroz Hartleys Limited, was reportedly supported by a range of new and existing sophisticated, professional and institutional investors.

The proceeds will be used to fund Vittangi Anode Project early works, including earthworks and site infrastructure at the Luleå anode refinery site, commencement of procurement of anode equipment and detailed engineering, scaled up EVA production, silicon anode scale-up including securing commercial site, and general working capital (including costs of the Placement).

Talga opens UK center for battery material technology

Talga Group has announced it has opened its new Battery Center of Excellence in Cambridge, UK. The center is a significant expansion of Talga’s UK R&D facilities, first launched in 2016.

Focusing on battery material innovations, development and characterization, the center is designed to complement Talga’s existing facilities in Sweden (Talnode®-C EV qualification production and battery

quality control labs) and Germany (processing technology scale-up and graphene production).

Talga updates on anode material testing results and plant expansion plans

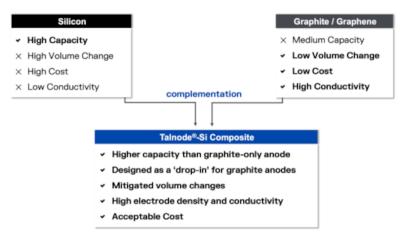

Talga Group has provided an update on commercialization and customer qualification of Talnode®-Si, the Company’s proprietary silicon anode product for lithium-ion (Li-ion) batteries. Talnode®-Si is a composite of graphite, graphene and ~50% silicon designed to significantly boost battery energy capacity when blended into existing commercial graphite anode materials.

Talga has been developing Talnode®-Si since 2018 at its facilities in Cambridge, UK, with commercial samples being produced at its pilot facility in Rudolstadt, Germany.

Talga to raise over USD$14,000,000

Talga Group has announced a fund raise of AUD$22 million (around USD $14,000,000). The raise was reportedly oversubscribed and was supported by a range of institutional investors. It will take Talga's pro forma cash position (before costs) at 30 September 2022 to A$27 million (around USD $17,255,000).

The Placement was jointly managed by Morgan Stanley Australia Securities Limited and Euroz Hartleys Limited, and supported by UK placing agent Longspur Capital Limited.

Talga and Mitsui collaborate on battery anode project

Battery and advanced materials company Talga is working with Mitsui & Co. Europe, a subsidiary of Mitsui, one of the largest global trading and investment companies based in Japan.

The MOU between the Companies, planned to take place until 31 August 2022, is based on the intent to advance potential co-development of Talga's Vittangi Anode Project in Sweden through a Joint Venture, and is expanded to include marketing, sales and partnership opportunities across Talga’s portfolio of lithium-ion battery products.

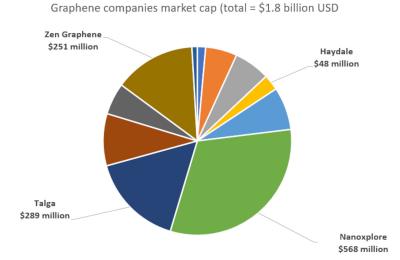

Public graphene companies reach almost $2 billion in market value

The graphene industry seems to be flourishing, at least when looking at the valuations of public companies. As we reported earlier this year, graphene stocks have risen nicely towards the end of 2020, and the trend continues in 2021 for most companies.

The total market value of graphene companies now reaches $1.8 billion USD for the 13 leading graphene public companies we track. It is important to note that not all this value is directly related to graphene - some of the companies have other activities, mainly graphite mining and supply. But for all these companies, graphene is a major part of the business, and most of the companies are pure-play graphene companies.

Talga reports positive results from marine real-world testing of its graphene-based coatings

Talga Resources has reported a milestone moment in a sea trial of its Talcoat graphene coating.

The company initially developed the graphene coating as an alternative to traditional coating methods that incorporate harmful chemicals and materials and first applied Talcoat to the hull of a ship back in late 2019 as part of a sea trial to test the coating’s robustness out in the tough ocean environment. A second application on a separate vessel followed soon after, and both trials remain ongoing.

Talga launches fully underwritten USD$18.8M placement to accelerate Vittangi Anode Project development

Talga has announced the launch of a fully underwritten institutional placement to raise USD$18.8 Million (AUD$25 million) before costs and a non-underwritten Share Purchase Plan to eligible shareholders to raise up to USD$7.5 Million (AUD$10 million).

has announced the launch of a fully underwritten institutional placement to raise USD$18.8 Million (AUD$25 million) before costs and a non-underwritten Share Purchase Plan to eligible shareholders to raise up to USD$7.5 Million (AUD$10 million).

Talga will use the proceeds to fund the Electric Vehicle Anode (EVA) pilot plant as part of the development of the Vittangi Anode Project located in northern Sweden.

Talga Resources receives government grant for anode refinery feasibility study

Battery anode developer Talga Resources has announced that it has received a commitment for a ~AU$1.8 million (around USD1.3 million) UK Government grant to complete a feasibility study into the commerciality of a Talga UK Anode Refinery.

Battery anode developer Talga Resources has announced that it has received a commitment for a ~AU$1.8 million (around USD1.3 million) UK Government grant to complete a feasibility study into the commerciality of a Talga UK Anode Refinery.

The UK government has recently announced a series of economic stimulus packages, including a £1 billion Automotive Transformation Fund (ATF), towards boosting the domestic electric vehicle and lithium-ion battery economy in collaboration between the Advanced Propulsion Centre, the Department for Business Energy and Industrial Strategy, Innovate UK and the Department for International Trade.

Talga Resources fast-tracks graphene-enhanced silicon anode product

Talga Resources has provided an update on the commercial progress of its graphene-enhanced silicon anode lithium-ion battery product Talnode-Si. Following encouraging early test results, further technical and commercial development of Talnode-Si has been underway at Talga’s facilities in Europe.

Talga Resources has provided an update on the commercial progress of its graphene-enhanced silicon anode lithium-ion battery product Talnode-Si. Following encouraging early test results, further technical and commercial development of Talnode-Si has been underway at Talga’s facilities in Europe.

Results from this latest phase of development reportedly show continued success of Talga’s silicon anode approach which uses lower-cost metallurgical-grade silicon for a high-energy density anode with mass-producibility potential.

Pagination

- Page 1

- Next page