Researchers at North Carolina State University and Pacific Northwest National Laboratory have found that graphene can enhance an important property of metals called the temperature coefficient of resistance.

They showed that mixing graphene in just the right proportion with copper could lead to improved electrical wires for more efficient electricity distribution to homes and businesses, as well as more efficient motors to power electric vehicles and industrial equipment. The team has applied for a patent for the work, which was supported by the Department of Energy (DOE) Advanced Materials and Manufacturing Technologies Office.

The temperature coefficient of resistance is a property that explains why metal wires get hot when an electric current runs through them. Researchers want to reduce this resistance while enhancing a metal's ability to conduct electricity. For several years, they have been asking whether metal conductivity can be increased, especially at high temperatures, by adding other materials to it. And if so, can these composites be viable at a commercial scale?

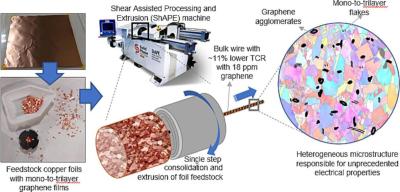

Now, they've demonstrated they can do just that, using a PNNL-patented advanced manufacturing platform called ShAPE.

When the research team added 18 parts per million of graphene to electrical-grade copper, the temperature coefficient of resistance decreased by 11 percent without decreasing electrical conductivity at room temperature. This is relevant for the manufacturing of electric vehicle motors, where an 11 percent increase in the electrical conductivity of copper wire winding translates into a 1 percent gain in motor efficiency.

"This discovery runs counter to what's generally known about the behavior of metals as conductors," said materials scientist Keerti Kappagantula. "Typically, introducing additives into a metal increases its temperature coefficient of resistance, meaning they heat up faster at the same current levels compared to pure metals. We are describing a new and exciting property of this metal composite where we observe enhanced conductivity in a manufactured copper wire."

Previously, the research team performed detailed structural and physics-based computational studies to explain the phenomenon of enhancing the electrical conductivity of metals using graphene.

In this study, they showed that the solid-phase processing used to extrude the composite wire leads to a uniform, near pore-free microstructure punctuated with tiny flakes and clusters of graphene that may be responsible for decreasing coefficient of resistance of the composite.

"We showed that flakes and clusters must both be present to make better conductors for high-temperature operations," Kappagantula said.

Co-authors Bharat Gwalani, Xiao Li, and Aditya Nittala took advantage of a PNNL-designed testbed that measures electrical properties with high precision and accuracy to validate the improved conductivity, as reflected in the team's detailed experimental analysis. Li and Md. Reza-E-Rabby developed the tooling and process envelopes for the solid-phase friction extrusion process that led to the patent.

When applied to any industrial application, the new copper-graphene composite wires will provide great design flexibility, according to the research team.

"Anywhere there's electricity, we have a use case," Kappagantula said.

For example, coiled copper wire forms are used in the core of electric motors and generators. Motors today are designed to operate within a limited temperature range because when they get too hot, the electrical conductivity drops dramatically. With the new copper-graphene composite, motors could potentially be operated at higher temperatures without losing conductivity.

Similarly, the wiring that brings electricity from transmission lines into homes and businesses is typically made of copper. As the population density of cities increases, demand for power follows suit. A composite wire that is more conductive could potentially help meet that demand with efficiency savings.

"This technology is a beautiful solution for copper wiring in high-density urban settings," Kappagantula added.

The research team continues its work to customize the copper-graphene material and measure other essential properties, such as strength, fatigue, corrosion, and wear resistance, which are crucial to qualify such materials for industrial applications. For these experiments, the research team manufactures wires about the thickness of a US penny (1.5 millimeters).

Physical properties of altered conductivity copper

Commercial winding of copper magnet wire is often at tensions of half the breaking strength of a given gauge. Any tensile strength shift in an improved new alloy would be news.

Drawing copper to size is a large percentage of wire cost. Any added graphene could alter this process for better or worse.