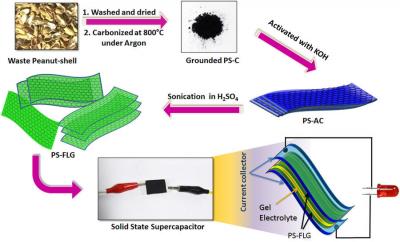

Researchers at India's Institute of Nano Science and Technology (INST) have developed a new route for the scalable preparation of large area few-layer graphene from waste biomass (nutshells) for high-performance energy storage devices.

The team's objective of using biomass-waste is not only to solve the problem of waste recycling but also to generate value-added materials like conductive graphene for renewable energy storage devices such as supercapacitors. The Peanut shell-derived graphene is said to possess remarkably high specific surface area (2070 m2 gâ1) and excellent specific capacitance. This method is reportedly scalable, renewable and cost-effective.

The researchers in this study have developed a new approach for the synthesis of few-layered graphene from no-value biomass waste peanut shell without using any graphitizing agents. The PS-FLG material is suitable for application in supercapacitors. The team also synthesized walnut shell and almond shell derived carbon for comparison purpose, and the PS-FLG possesses approximately four times more specific capacitance than WS-C and two times more than AS-C.