Researchers from AMO GmbH, RWTH Aachen University, Chalmers University and the University of Wuppertal have recently developed a novel type of graphene-based flexible energy harvester, which reportedly shows good prospects for powering wearable and conformal devices.

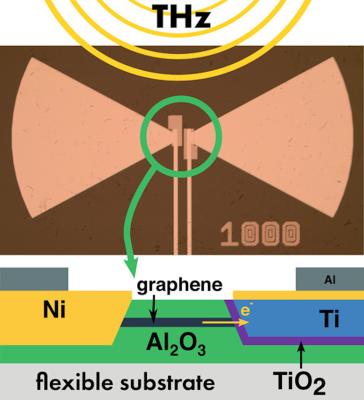

The device is a 'rectenna' - an antenna directly coupled to a diode, which is able to detect radiation and to transform it into a DC output. Rectennas working in the microwave region have been well established since the sixties, thanks to the availability of Schottky diodes with a sufficiently short response time. The challenge is to extend the working principle of rectennas to higher frequency ranges in particular terahertz (THz) and optical frequencies.

One of the big advantages of the device developed by Hemmetter and co-workers is that it can be produced on flexible thin-film substrate, overcoming the form factor limitations of silicon electronic chips. The key is the use of metal-insulator-graphene (MIG) diode. The high charge carrier mobility and the flexibility of graphene allow realizing devices that combine excellent DC performance with high cut-off frequencies, and to do so on flexible substrates.

In fact, the rectenna by Hemmetter and co-workers exploits a one-dimensional MIG diode, meaning that the junction area in the diode has just the thickness of the graphene sheet itself, which is about 0.3 nm. This change in geometry with respect to conventional MIG diodes has a huge impact, as it reduces both the capacity and the resistance of the junction, increasing its operating frequency and thus the performance of the rectenna.

Another interesting aspect of the work is that the process for developed for fabricating the rectennas based on one-dimensional MIG diodes is scalable and compatible with conventional thin-film technology and with high-throughput.

Our results are very encouraging, says Zhenxing Wang, leader of the Graphene Electronics Group at AMO, and corresponding author of the paper. They point towards the possibility of using rectennas arrays as power supplies for wearable devices or self-powering sensors.