MIT engineers recently managed to create cell-sized robots that could collect data about their environment, but were quite tricky to manufacture. Now, the team has found a way to mass produce these synthetic cells (syncells) through controlled fracturing of graphene.

The previously developed MIT robots were so small, that there was no point trying to steer them, but they could still sense and observe, scanning their surroundings and storing data for long periods of time. Later, they could be filtered out and analyzed to get a reading of water quality, for example, or biomarkers for disease in a patient's bloodstream.

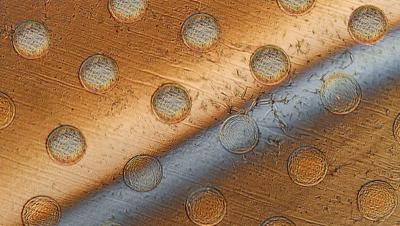

First, the electronics are encased in a polymer material. Then, tiny dots of it are deposited onto a flat sheet of graphene by a micro-array printer, before another layer of graphene is laid out over the top. As the top layer settles it will drape down over the dots.

Next, the graphene is stressed to the point that it fractures. But rather than shattering randomly, the material will break off at the strain points around each dot, leaving a series of syncells that look like they've been neatly hole-punched out. Better yet, the edges of the two graphene layers end up sticking together, wrapping the electronic components safely inside.

"This general procedure of using controlled fracture as a production method can be extended across many length scales," says Albert Liu, co-author of a study describing the method. "[It could potentially be used with] essentially any 2D materials of choice, in principle allowing future researchers to tailor these atomically thin surfaces into any desired shape or form for applications in other disciplines."

The syncells can store information in a memory array, which can be read later using an electrical probe and erased for reuse. As a test, the team encoded the letters M, I and T into a memory array within a syncell, and showed that it was readable, even after months of floating around in water. That data can even be stored without power.

In the future, this mass production method could be used to make syncells with more functionality, like those used in the earlier study.