Researchers at Rensselaer Polytechnic Institute have developed a new microfluidics-assisted technique for developing high-performance macroscopic graphene fibers. Graphene fiber have potential applications in diverse technological areas, from energy storage, electronics, optics, electro-magnetics, and thermal conductors, to structural applications.

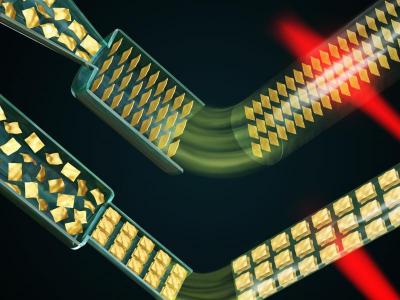

Sheet alignment and orientation order of graphene structures induced by microfluidics design enable the microstructure control and optimization of thermal-mechanical and electronic properties of macroscopic graphene fibers

Sheet alignment and orientation order of graphene structures induced by microfluidics design enable the microstructure control and optimization of thermal-mechanical and electronic properties of macroscopic graphene fibers

The team explained that It has been historically difficult to simultaneously optimize both the thermal/electrical and the mechanical properties of graphene fibers. However, the Rensselaer team has demonstrated their ability to do both.

The control of different flow patterns offers a unique opportunity and flexibility in tailoring macroscopic graphene structures from perfectly aligned graphene fibers and tubes to 3D open architecture with vertically aligned graphene sheet arrangement, said Jie Lian, a professor in the Rensselaer Department of Mechanical, Aerospace, and Nuclear Engineering (MANE) and the lead author on the article.

This research paves the way for new sciences to optimize the fiber assembly and microstructure to develop high-performance graphene fibers, said Lian. This approach could be extended to other materials to manufacture hierarchical structures for diverse functional applications.