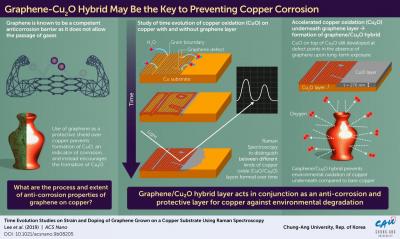

Scientists from Chung-Ang University, Korea, led by Prof Hyungbin SonKorea, have observed a unique way in which graphene forms a hybrid layer that prevents copper corrosion.

A challenge with using copper is that its surface oxidizes over time, even under ambient conditions, ultimately leading to its corrosion. Thus, finding a long-term method to protect the exposed surfaces of copper is a valuable goal. One common way of protecting metal surfaces is by coating them with anti-corrosive substances. Graphene is studied extensively as a candidate for anti-corrosive coating, as it serves as a barrier to gas molecules. But, despite these properties, graphene sheets have been said to protect copper from corrosion only over short periods (less than 24 hours). In fact, surprisingly, after this initial period, graphene appears to possibly increase the rate of copper corrosion, which is completely in contrast to its anti-corrosive nature.

To shed light on the peculiar nature of graphene seen in copper, the Korean research team studied graphene islands on a copper substrate to analyze the patterns of its corrosion. Prof Son explains: "Graphene is known to be mechanically very strong and impermeable to all gases, including hydrogen. Following studies claiming that the corrosion of copper substrates was accelerated under graphene through various defects, these properties have attracted great attention as an oxidation barrier for metals and have been controversial for over a decade. However, they have not been qualitatively investigated over longer time scales. Thus, we were motivated to study the role of graphene as a corrosion-resistant film at the graphene-copper interface." Prof Son and his team used Raman spectroscopy, scanning electron microscopy, and white light interferometry to observe the trends in copper corrosion for 30 days.

At first, the team detected corrosion developing at the edges, spreading the oxidized form of copper, copper oxide (Cu2O), at various defects such as edges, grain boundaries, and missing atoms. This resulted in the splitting of water vapor, supplying oxygen for the oxidation process, until the entire barrier seemed to be rendered useless and copper was fully corroded underneath. Owing to graphene's effect on ambient water vapor, the protected portion of the copper substrate was more corroded than the unprotected portion. Over time, the formation of Cu2O underneath the graphene sheet dispersed the strain and caused p-doping in graphene-creating a hybrid-like structure. But, after 13 days of exposure to ambient conditions, the team discovered something new. They observed that that the corrosion had significantly slowed down where a new hybrid of graphene and Cu2O layer had formed. Meanwhile, the unprotected copper continued to corrode at a consistent rate, until it had penetrated far deeper than the corrosion under the graphene shield.

These findings show that graphene, in fact, protects copper from deep, penetrating oxidation, unlike what previous studies had concluded. Prof Son explained, "We observed that over a longer time scale (more than 1 year), the graphene-Cu2O hybrid structure became a protective layer against oxidation. The area beyond the graphene was heavily oxidized with CuO, with a depth of 270 nm."

Prof Son concludes, "For nearly a decade, graphene's anti-corrosive properties have been controversial, with many studies suggesting that graphene accelerates the oxidation of copper (resulting in its corrosion). We have shown for the first time that the graphene-Cu2O hybrid structure, which forms over a long period, significantly slows down the oxidation of copper in the long term, as compared to bare copper."