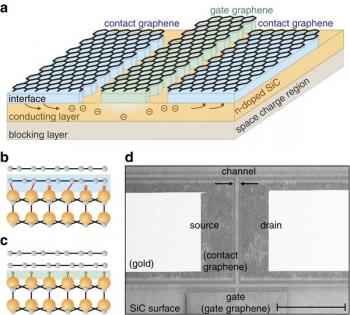

Researchers from Germany and Sweden developed high-performance monolithic graphene transistors using a simple lithographic etching process. The process involves heating silicon carbide, removing the silicon atoms (which leaves a single graphene sheet). A lithographic mask is laid down, and reactive ion etching is used to define the transistors. Hydrogen gas was introduced during the growth of the middle graphene channel, turning it from contact (source/drain) graphene into gate graphene.;

In the current process, each transistor is about 100 micrometers across, so they cannot tell how fast this transistor will be in small scale. Currently the performance corresponds well with textbook predictions for the cutoff frequency of a metal-semiconductor field-effect transistor. They say that some "very simple changes" could increase performance by about 30.