Researchers from the Russia-based Moscow Institute of Physics and Technology ('MIPT') have developed biosensor chips of unprecedented sensitivity, which are based on copper combined with graphene oxide instead of the conventionally used gold. In addition to making the device somewhat cheaper, this innovation will facilitate the manufacturing process.

The Russian research team's biosensing chip reportedly achieved unmatched sensitivity, and yet its configuration is mostly standard and therefore compatible with existing commercial biosensors, e.g. Biacore, Reichert, BioNavis, or BiOptix.

The most common material used in optoelectronics and photonics is gold and nearly all commercial biosensor chips incorporate gold films several tens of nanometers thick. The reason gold is so ubiquitous is that it has excellent optical properties and is chemically very stable. But even gold is not perfect. For one thing, it is expensive â specifically, high-purity gold costs over 25 times as much as high-purity copper. Also, gold is incompatible with the industrial processes used for manufacturing microelectronics, which severely limits its potential for application in device mass production.

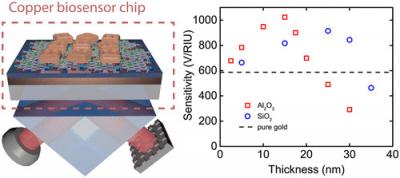

Unlike gold, copper does not have these flaws. Its optical properties are on par with those of gold. Copper is used as an electrical conductor in microelectronics. However, it suffers from oxidation, or corrosion, and therefore has not been used in biochips. Now, the MIPT researchers have solved this problem by covering the metal with a 10-nanometer dielectric layer. In addition to preventing oxidation, this altered the optical properties of the chip, making it more sensitive.

To further refine their biosensor design, the authors added a graphene oxide layer on top of the copper and dielectric films, enabling unprecedented sensitivity.

It is known that copper is susceptible to the corrosive influence of the environment. We have shown that protective dielectric films only tens of nanometers thick do more than just prevent oxidation: In some cases, they increase biosensor sensitivity, says Yury Stebunov, the lead author of the paper and co-founder and CEO of GrapheneTek LLC. We don’t see purely fundamental research as the final destination. Our solution will be available to potential customers before the end of the year. The technologies proposed in this study could be used to create miniature sensors and neural interfaces, and that’s what we’re working on right now.