Laser-induced graphene has defects that can be turned into supercapacitors

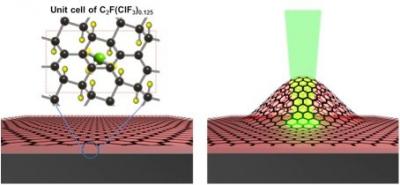

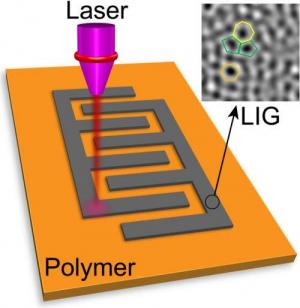

Researchers at the Rice University have devised a process in which a computer-controlled laser burns through a polymer to create flexible, patterned sheets of multilayer graphene that may be suitable for electronics or energy storage. The process works in air at room temperature, cancelling the need for hot furnaces and controlled environments.

The product of this process is not a 2D piece of graphene but a porous foam of interconnected flakes about 20 microns thick. The laser doesn't cut all the way through the base material, so the foam remains attached to a flexible plastic base.