Archer Materials has progressed its graphene-based biosensor technology development by successfully prototyping key device hardware using additive manufacturing (3D printing).

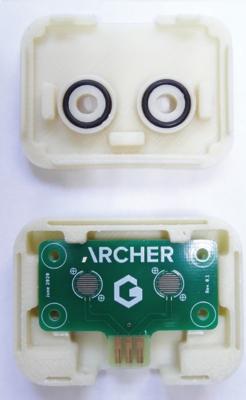

Graphene-based biosensor devices 2D printed on a circuit board that has been incorporated into the custom-designed and 3D printed cartridge made from ABS. The cartridge is opened and the interior is shown.

Graphene-based biosensor devices 2D printed on a circuit board that has been incorporated into the custom-designed and 3D printed cartridge made from ABS. The cartridge is opened and the interior is shown.

The cartridges were reportedly printed using acrylonitrile butadiene styrene (ABS), a robust engineering plastic, in less than 2 hours and with low costs, with the cartridges weighing about 13 grams (similar to a AAA battery) and measuring a few centimetres in size (palm size).

When the Company undertook the recent Share Purchase Plan the main purpose of the fund raising was to allow the Company to accelerate the pace of development of our key projects and technologies.

The 3D printing of biosensor components is consistent with that strategy.

Archer has access to excellent infrastructure, facilities, R&D personnel, and 3D and 2D printers through the company’s collaboration with the University of Adelaide, as a founding industry partner of the ARC Research Hub for Graphene Enabled Industry Transformation (ARC Graphene Hub).

An international patent has now been published by the World Intellectual Property Organization (WIPO) to protect and commercialize intellectual property (IP) associated with the graphene-based biosensor materials technology.