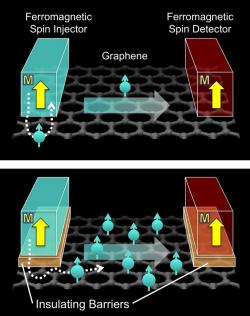

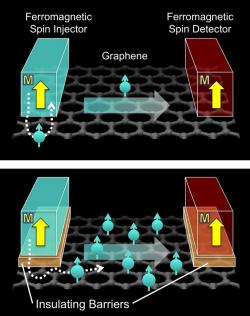

Researchers from the University of California, Riverside successfully achieved tunneling-spin-injection into Graphene. The researchers inserted a nanometer-thick insulating layer, known as a tunnel barrier, in between the ferromagnetic electrode and the graphene layer. They found that the spin injection efficiency increased dramatically. A 30-fold increase, actually. This could lead to graphene-based Spintronic devices.

The team also made an unexpected discovery that explains short spin lifetimes of electrons in graphene that have been reported by other experimental researchers. People usually assume that the Hanle measurement accurately measures the spin lifetime, but this result shows that it severely underestimates the spin lifetime when the ferromagnet is touching the graphene, said Wei Han, the first author of the research paper and a graduate student. This is good news because it means the true spin lifetime in graphene must be longer than reported previously potentially a lot longer.