Graphene Labs successfully managed to convert Lomiko Metal's Quatre Milles property graphite to graphene

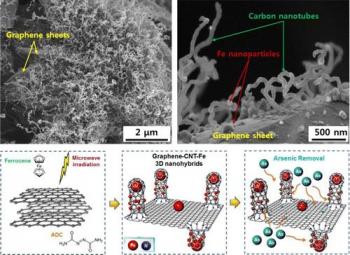

Graphene Laboratories announced that they have successfully managed to convert Lomiko Metal's Quatre Milles property graphite to graphene. They have actually produced graphene oxide (GO) and reduced graphene oxide (RGO) samples. The companies hope that they will be able to create graphene materials on a larger scale and at a reduced price.

Graphene Laboratories announced that they have successfully managed to convert Lomiko Metal's Quatre Milles property graphite to graphene. They have actually produced graphene oxide (GO) and reduced graphene oxide (RGO) samples. The companies hope that they will be able to create graphene materials on a larger scale and at a reduced price.

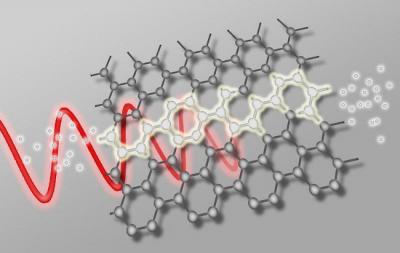

In the first step of the conversion process the natural graphite flakes were oxidized and turned into GO by modified Hummer's method. This resulted in a stable aqueous dispersion with concentration of 40 g/L. The GO was then converted into RGO, with a surface area of 500 m2 /g and an electrical conductivity 4 S/cm.