Green graphene-oxide reduction enabled by UV irradiation in water

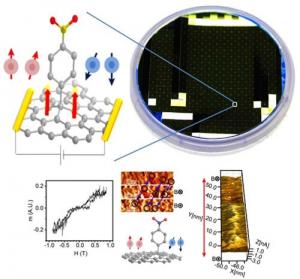

Reduced graphene oxide is a promising way to produce graphene materials, but currently used methods use harsh chemicals and are not environmentally friendly. A possible green method is photoreduction, but the dynamics behind this reduction aren't fully understood.

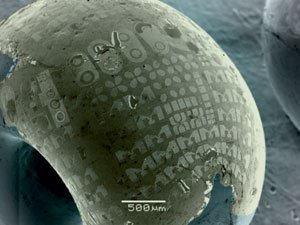

Now researchers from Germany's Max Planck Institute demonstrate and measure the ultrafast (picosecond) ultimate and fundamental time scale of graphene oxide photoreduction. The researchers explain that their research demonstrates the nature and fundamental timescale of GO reduction in water by UV irradiation.