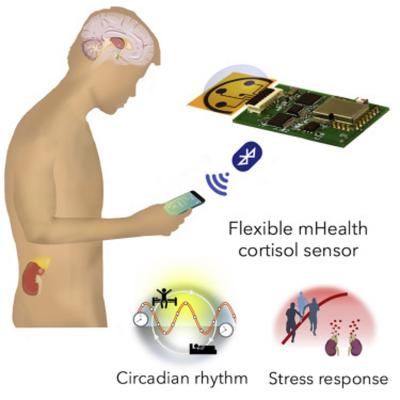

A new graphene-based sensor that measures stress via cortisol in sweat could be used by NASA to gauge the anxiety levels of astronauts.

Developed by Caltech assistant professor of medical engineering, Wei Gao, the device features a plastic sheet etched with a laser to generate a 3D graphene structure with tiny pores in which sweat can collect. Those pores create a large amount of surface area in the sensor, which makes it sensitive enough to detect compounds in the sweat that are only present in very small amounts. Those tiny pores are also coupled with an antibody sensitive to cortisol, allowing the sensor to detect the compound.

We aim to develop a wearable system that can collect multimodal data, including both vital sign and molecular biomarker information, to obtain the accurate classification for deep space stress and anxiety, he said.

Our analysis time could be only a few minutes. Typically, a blood test takes at least one to two hours and requires stress-inducing blood draw. For stress monitoring, time is very important.

Aside from aerospace applications, the device could be used to help monitor and treat a range of conditions. Cortisol levels rise and fall in line with a regular daily rhythm, but according to Gao, various mental health conditions have subtle changes on these cycles. Monitoring cortisol over a number of days could help with the diagnosis of these conditions, potentially leading to better treatment.

Depression patients have a different circadian pattern of cortisol than healthy individuals do, said Gao. With PTSD patients, it’s another different one.