A team of researchers at MIT developed a method of coating condensers used in power plants with graphene, to make them durable and transfer heat rapidly. Condensers are the equipment that collects steam and condense them back to water in electricity-producing plants. Improving their efficiency could greatly contribute to the overall power plant efficiency.

The scientists coated the condenser surfaces with a layer of graphene, and found that this can improve the rate of heat transfer by a factor of four. The improvement in condenser heat transfer could lead to an overall improvement in power plant efficiency of 2 to 3 percent, enough to make a significant change in global carbon emissions.

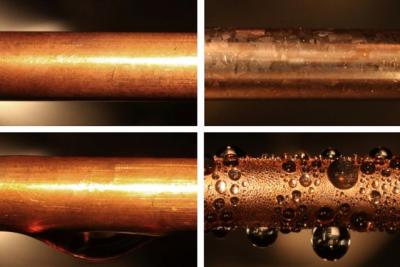

An important part of condenser improvement is repelling water to prevent steam-film formation that impedes heat transfer, and since graphene is hydrophobic by nature, the scientists examined how coating the condensers with it would work. They found that the single-atom-thick coating of graphene improved heat transfer fourfold compared with surfaces where the condensate forms sheets of water, such as bare metals. Further calculations showed that optimizing temperature differences could boost this improvement to 5 to 7 times. The researchers also showed that after two full weeks under such conditions, there was no measurable degradation in the graphene’s performance.