Umeå researchers have shown how activated graphene, activated carbons and other hydrophobic carbons can be dispersed in water in a form of micrometer-sized particles. The key agent that helps to make these dispersions last for days is the use of graphene oxide. The authors have applied for patent for the method to prepare dispersions.

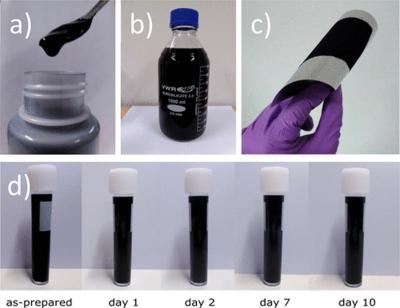

(a)a dense a-rGO aqueous dispersion (b)The dispersion can be prepared in liter amounts. (c)The a-rGO dispersion deposited and dried on a flexible stainless steel substrate shows good adhesion even under bending conditions. (d)Dispersions remain stable

(a)a dense a-rGO aqueous dispersion (b)The dispersion can be prepared in liter amounts. (c)The a-rGO dispersion deposited and dried on a flexible stainless steel substrate shows good adhesion even under bending conditions. (d)Dispersions remain stable

The team explained that graphene, graphite and activated carbons are quite different forms of carbon but they have hydrophobic properties in common. On the other hand, using dispersions or solutions for many applications is a big advantage. Ideally, one can spray or paint graphene dispersion on metal foil and prepare e.g. electrode material by simply drying.

the researchers from Umeå University have found a simple and environmentally friendly solution to the problem: using graphene oxide, that is hydrophilic and easy to disperse in water.

What we discovered is that stable water dispersions can be prepared by adding certain amount of graphene oxide to various hydrophobic carbons, says Alexandr Talyzin, Associate Professor at the Department of Physics at Umeå University.

His team of physicists tested the method using high surface area carbons like graphene, activated graphene, porous or activated carbons. The dispersions were stable and did not precipitate even after days of shelf storage. When they added some carbon nanotubes into the dispersion, it appeared to be rather good for preparation of supercapacitor electrodes. The dispersion was applied to metallic foil, dried and heated at 200o Celsius. All these steps could easily be scaled up to industrial production, the researcher suggest.

What we get in the end is a thin film of conductive electrode material with rather high surface area, good conductivity and excellent performance in storage of electricity in supercapacitors. The high surface area is provided by the micrometer-sized particles of e.g. activated graphene, while nanotubes and thermally reduced graphene oxide provide good electrical contact between the particles, says Alexandr Talyzin.

The dispersions can also be useful in many other applications like inks for printing, protective coatings, and conductive paints.