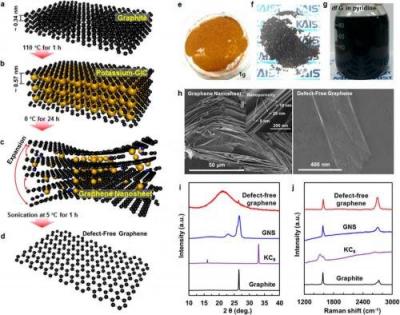

Researchers at from Korea's KAIST institute developed a new method to fabricate defect-free graphene. Using this graphene, they developed a promising high-performance anode for Li-Ion batteries.

The method starts with a Pyrex tube and fill it with graphite powder. The open-ended tube is placed in another, larger tube and potassium is added to the gap between the tubes. The tubes are sealed and heated - which causes the potassium to move inside the micropores in the graphite powder - creating a potassium-graphite compound. This is placed in a pyridine solution, which expands the layer and separates them to form graphene nanosheets - which are then exfoliated to create a single graphene sheet.

This creates a defect-free graphene. The size of the sheets is created by changing the temperature of the exfoliating step.

To demonstrate their graphene sheets, the researchers wrapped them around Co3O4 particles, and used it to create a Li-Ion battery anode. They say this anode lasts longer than pure-graphene anodes.