Scientists from Imperial College London and Catania University & CNR-IMM have developed a novel graphene ink that can be used to detect a variety of chemical substances when layered on top of commercially available printed circuit boards (PCBs) as a thin film.

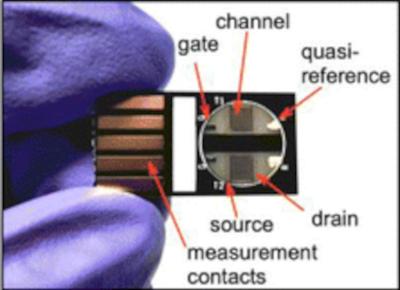

In their recent paper, the team demonstrated a novel and versatile sensing platform, based on electrolyte-gated graphene field-effect transistors, for easy, low-cost and scalable production of chemical sensor test strips. The Lab-on-PCB platform is enabled by low-boiling, low-surface-tension sprayable graphene ink deposited on a substrate manufactured using a commercial printed circuit board process.

The researchers say that the technology may pave the way for a low-cost multi-sensor arrays that can be deployed in healthcare, industry and more.

The first printed graphene field-effect transistors from graphene inks were demonstrated in 2011 by the group of Dr. Felice Torrisi, achieving an incredibly high mobility of electrons compared to standard printed transistors. Such properties make graphene attractive for sensing applications. Since it is a 2D material, graphene has a large surface area that can interact with any gases or liquids it is exposed to – allowing it to be effectively used to detect specific chemicals. Furthermore, it is relatively easy to modify to sense different substances because of its unique carbon-based chemistry.

“You can either bond receptors to the surface of graphene or bring the receptors close enough to stick to the surface, but not actually bond to it,” says Benji Fenech Salerno, a PhD student in the Department of Chemistry and co-lead author of the recent paper. “In both cases, this allows us to add chemical selectivity to graphene,” he says.

The research team demonstrated that their technology using graphene ink that was sprayed onto a PCB was able to accurately detect the pH and sodium ion concentration of an aqueous solution.

Future plans include expanding the technology to other analytes, as well as depositing graphene inks on different surfaces.

The researchers say that though graphene inks have been produced before, it has been difficult to commercially synthesize them with a high concentration of graphene flakes and to deposit the inks as a thin, stable layer on top of a commercial PCB surface.

Previous challenges were that the inks had the tendency to laminate off their substrates. In other words, they would peel off the surfaces they were deposited on. This would introduce a source of error into any measurements that are made, reducing their accuracy as chemical sensors.

Dr. Felice Torrisi, a senior lecturer in the Department of Chemistry and corresponding author of the paper, also says that it was difficult for researchers to create high concentration dispersions of graphene. “That has been, until now, a large unsolved challenge with these inks – the amount of graphene that you get per unit volume, which tends to be very low compared to other commercial inks with, for example, metallic nanoparticles,” he says.

Low-concentration inks can pose complications when trying to apply them in sensor technologies. Having to spray the inks repeatedly onto the substrate to get a sufficient coating can lower the sensor’s overall performance, the researchers say.

The team overcame both obstacles by introducing a special stabilizer known as polyvinylprrolidone (PVP) – a polymer that is often used as a binder. The addition of PVP allowed the ink to be stable at higher concentrations and gave it a longer shelf life.

The stabilized graphene ink was also self-adhesive, allowing it to stick to the surface of a commercially available PCB without laminating. “Enabling the integration of graphene ink with PCB boards is not simple: it’s difficult to find the appropriate formulation to have strong adhesion,” Dr. Torrisi says. “Depositing graphene inks on commercial PCB boards reliably, opens up to large scale integration of printed graphene sensors in commercial products” he adds.

The new formulation allows the team to design graphene inks sensitive to specific chemicals, which can then be sprayed onto a relatively cheap PCB for a low-cost sensor. Different receptors may then be deposited onto the same sensors allowing for multiple substances to be detected on the same device. “We want to bring these sensors close to the end user,” Benji says.

The team gives the example of a metabolic panel, a type of diagnostic test that is often prescribed to patients. “If you suffer from a chronic condition, it is an inconvenience to have to go to a clinic quite often, or maybe you don’t get tested as often as you would like".

Having low-cost sensors may allow users to perform tests themselves. Other applications could also be rapid chemical detection in areas like agriculture or industry as the technology the Imperial team developed is able to give results within 60 seconds, they say.

The team has now filed a patent for their technology, and are exploring expanding its versatility to detecting other analytes.

The scientists are also investigating how to deposit graphene inks onto other surfaces, such as the surface of skin.