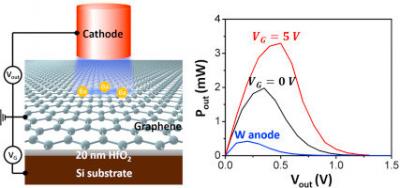

Researchers at Stanford University have recently demonstrated a graphene-based high efficiency thermal-to-electricity conversion technology, called thermionic energy convertor. By using graphene as the anode, the efficiency of the device is increased by a factor of 6.7 compared with a traditional tungsten anode. This technology can work in a tandem cycle with existing thermal-based power plants and significantly improve their overall efficiencies.

Hongyuan Yuan and Roger T. Howe, among the leading researchers in the Stanford team, explain that one of the major challenges for wide adoption of TECs is high anode work function, which directly reduces the output voltage as well as the net efficiency. The theoretical maximum efficiency for a TEC with a 2 eV work function anode is 3% at a cathode temperature of 1500 K, compared to an astonishing 10-fold increment to 32% with a 1 eV work function anode.

Before the discovery of graphene, the world-record low work function for a conductor was around 1.1 eV to 1.2 eV, which is achieved by lowering the vacuum level through the deposition of a monolayer of CsO on the surface. Superior to any 3D traditional metal, the work function of graphene can be reduced by not only lowering its vacuum level, but also raising its Fermi level by electrostatic gating through a back gate at the same time. In this approach, researchers discovered that the work function of graphene reached a new world-low record of 1.0 eV in 2015.

The second major challenge to the success of TEC is high space charge barrier between TEC’s cathode and anode, which directly reduces the output current and thus the net efficiency. In order to reduce the space charge barrier, TEC requires a very small vacuum gap to separate the cathode and anode, usually around 10 mm. If the gap is much larger than 10 mm, all the benefit that an ultra-low work function anode could bring would be diminished. In this recent work, the team successfully addressed the above mentioned two challenges, and demonstrated that the previously discovered ultra-low work function graphene can indeed be applied to TEC with a significant amount of efficiency enhancement. Compared to a traditionally used tungsten anode, the net efficiency is increased by a factor of 6.7.

The current demonstration of the TEC device is done in an ultra-high vacuum chamber, with many pumps constantly pumping down the pressure. In reality, it will be vital to fabricate such a TEC device and seal it in a vacuum ‘chip’ using nano/micro fabrication techniques. Only by making the device small and reliably stable would it be economically feasible in the sustainable energy industry.

The team envisions such a TEC device in the future, which is sealed in a small and thin cell (TEC cell). To generate electricity, all you need to do is to attach one side of the cell to a heat source. You may attach a couple of the TEC cells to the water heater at your home to charge your phone. Or attach many TEC cells to a fossil-fuel power station to improve its overall efficiency.

Thermionic energy convertors (TECs) were primarily used as the energy source for satellites. However, TEC research and its application stagnated until recently. Over the past ten years, with the development in modern wafer-scale fabrication techniques, device physics and material science, as well as an increasing attention to clean and renewable energy globally, TEC has again received a considerable amount of interest both in the academia and industry. Despite the limited application at the moment, with improvement in efficiency and device stability, TECs are expected to see an enormous market both in the centralized power plants, i.e. in a tandem cycle, as well as in the distributed systems, e.g. automobiles with internal combustion engines and domestic houses with water heaters.

TEC cells surrounding ICs, now!

C'mon guys, build these around micro-ccts, ICs etc so they absorb most of the heat dissipated by the IC then feed that power back into the IC device. Result? Likely 80-90% reduction in power consumption and external surface heat-rise. Save the planet in one swipe. Cheers, Chrys