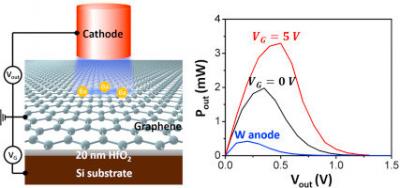

Researchers design non-volatile switches that manipulate light using phase-change materials and graphene heaters

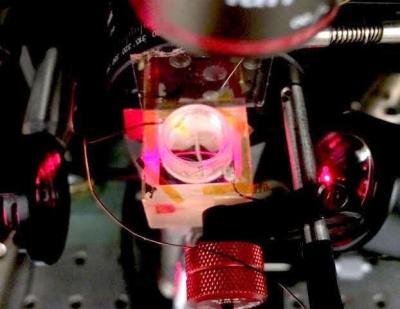

A team of researchers from Stanford University, University of Washington, The Charles Stark Draper Laboratory, University of Maryland and MIT have reported the design of an energy-efficient, silicon-based non-volatile switch that manipulates light through the use of a phase-change material and graphene heater.

Data centers are dedicated spaces for storing, processing and disseminating data, that enable various applications, from cloud computing to video streaming. In the process, they consume a large amount of energy; As the need for data use grows, so does the need to make data centers more energy-efficient.