As electronics keep shrinking in size, several problems arise. One of these is that the copper wires that connect transistors to form complex circuits need to be very thin, but carry so much current that can cause them to break apart due to atoms being knocked out of place. One way of solving this, studied by a group led by Stanford University, is to wrap copper with graphene. The group found that this can alleviate this major problem called electromigration.

This was presented at a recent IEEE meeting that addressed the coming problems for copper interconnects and debated ways of getting around them. Growing graphene around copper wires can help prevent electromigration, and also seems to bring down the resistance of the copper wires. Generally speaking, the narrower the wire, the higher its resistance. Interconnects have had to shrink while increasing the current densities by 20 times, said Intel Fellow Ruth Brain at the meeting.

The semiconductor industry avoids integrating new materials as long as possible, but Standorf scientists say there isn’t much choice in this situation: If copper’s life can’t be extended, it will have to be replaced with a new material anyway, such as cobalt.

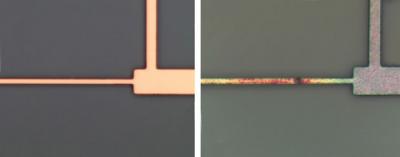

The Stanford group worked with Lam Research Corp., which makes chip manufacturing tools, as well as researchers from Zhejiang University, in China, to make and test the composite interconnects. The materials make a good pair; graphene is often made by growing it on copper. Lam Research has developed a proprietary process for doing this at temperatures that won’t damage the rest of the chipâbelow 400 °C. Compared to copper alone, the composite limited electromigration by a factor of 10, and the composite wires had half the electrical resistance.

The Stanford team says the interconnect problem can no longer be dismissed. Before, most of the time we were hearing about transistors. Now it’s not just transistors but wires, memoryâmany other things that were previously not a problem are beginning to be a problem.