Graphene achieves superconductivity

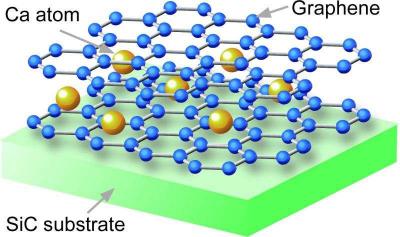

A collaborative team from Tohoku University and the University of Tokyo has designed a way to make graphene superconductive, which means electrons can flow through it with zero resistance. This can lead to significantly more efficient electronic devices, power lines, high-speed electronic devices and more.

While exciting, it is important to say that this demonstration of superconductivity in graphene occurred at a temperature of -269 degrees Celsius, and room temperature superconductivity is still far from attainable. However, this research does suggest that graphene could be used to build nano-sized, high-speed electronic devices.