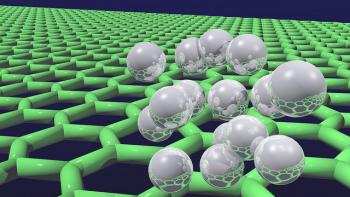

Charged defects in graphene can increase its energy storage abilities

Scientists at the University of California, San Diego discovered a method to increase the amount of electric charge that can be stored in graphene, in a research that may provide a better understanding of how to improve the energy storage ability of capacitors for potential applications in cars, wind turbines, and solar power.

The team attempted to introduce more charge into a capacitor electrode using graphene as a model material for their tests. The idea is that increased charge leads to increased capacitance, which translates to increased energy storage.