The University of Manchester installs a powerful high res microscope, will be used for graphene research

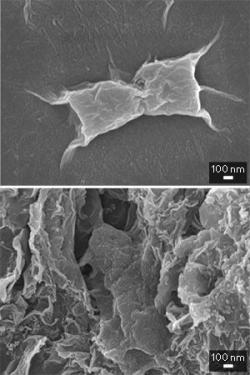

The University of Manchester have installed one of the world's most powerful high-res microscopes, the FEI Titan G2 80-200 scanning transmission electron microscope (S/TEM). The Titan G2 80-200 S/TEM will enable researchers to study the structure and elemental composition of materials at the atomic level.

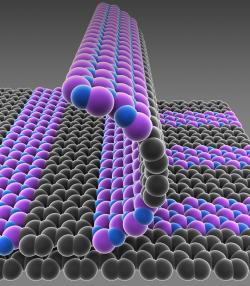

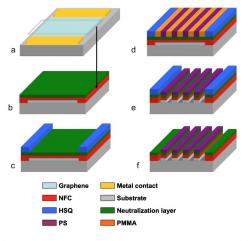

This new microscope may also help the University's graphene research - the Titan microscope's high-angle, dark-field imaging capability can potentially enable the discovery of new information about the electrical properties of graphene.