Flexible transparent graphene electrodes may enable electronic tattoos

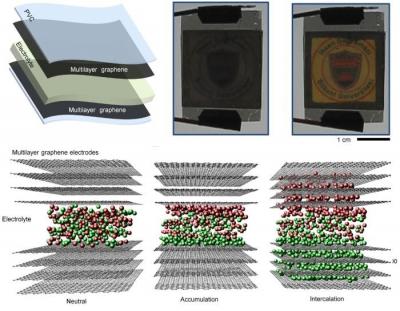

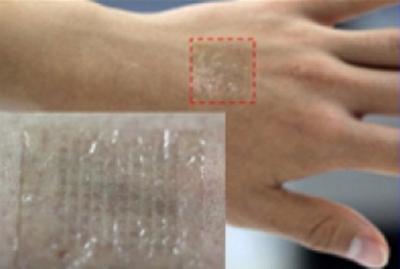

Researchesr from Korea's Ulsan, KAIST and ETRI institutes developed a process that produces flexible transparent graphene electrodes that can be attached to the skin (or any kind of delicate object). This could enable applications such as electronic tattoo-like stickers or bio-signal sensors.

A graphene metal fiber composite ise used, which lowers the resistance of the transparent electrode to approximately 1/20th of existing ones. This enables the electrodes to be used in flexible displays or sensors. The new process is similar to a widely-used semiconductor process which means that this can be scaled commercially.