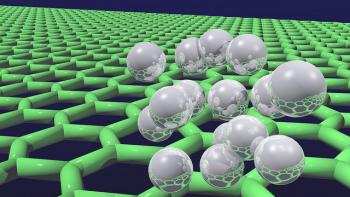

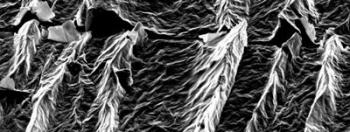

Wrinkled graphene oxide could create body-like surroundings for cell growth

Brown University researchers developed a simple method of creating environments on which to culture cells using graphene, that relies on a technique that makes small wrinkles in graphene sheets. These textured surfaces for culturing cells in the lab manage to copy the intricate environment in which cells grow in the body.

Cell culture is usually done in the lab in petri dishes and on other flat surfaces. The body, however, creates much more complex environments for cells to grow. Research has shown that a cell’s physical surroundings can influence its shape, physiology, and even the expression of its genes, so scientists are looking for ways of culturing cells in lab conditions that are a bit more complex and close to body-made environments. The surfaces might also be used to test drugs in the lab, or perhaps as biomimetic surfaces for implantable tissue scaffolds or neural implants.