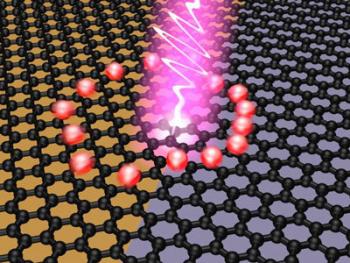

FlexEnable joins the Graphene Flagship and details its graphene plans

UK-based FlexEnable has recently joined the Graphene Flagship and announced its plans for this year, which will mainly focus on developing new use cases for graphene in flexible electronics including highly conductive interconnect lines and barrier films.

UK-based FlexEnable has recently joined the Graphene Flagship and announced its plans for this year, which will mainly focus on developing new use cases for graphene in flexible electronics including highly conductive interconnect lines and barrier films.

Starting April 2016, the Graphene Flagship is scheduled to move into its core project phase, where FlexEnable’s expertise in industrializing flexible electronics will be utilized to harness the potential of graphene and other 2d materials. FlexEnable’s Cambridge fab will play an important role in showcasing graphene’s performance over surfaces of all sizes, including large areas as well as in the development of advanced product concepts.