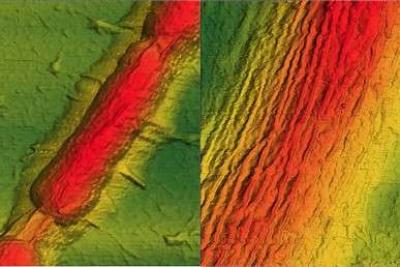

Dassi unveils graphene-enhanced bike

British-based Dassi Bikes unveiled what they referred to as "the world’s first bike made with graphene" at their headquarters in Hampshire.

Dassi is currently focusing on a single road frame & TT frame design. The Dassi bike frame is said to contain 1% graphene throughout six layers underneath the carbon surface layer. The frame weighs just 750g and engineers predict that sub 400g frames could be achievable.