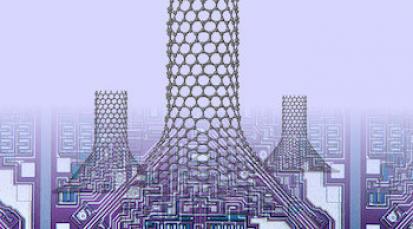

Researchers at Rice University have found that it may be possible to make graphene-carbon nanotube junctions excel at transferring heat, turning these into an attractive way to channel damaging heat away from next-generation nano-electronics. This could, in theory, be done by putting a cone-like chimney between the graphene and nanotube to eliminate the barrier that blocks heat from escaping.

Graphene and carbon nanotubes both excel at the rapid transfer of electricity and phonons, but when a nanotube grows from graphene, atoms facilitate the turn by forming heptagonal (seven-member) rings instead of the usual six-atom rings. Scientists have determined that forests of nanotubes grown from graphene are excellent for storing hydrogen for energy applications, but in electronics, the heptagons scatter phonons and hinder the escape of heat through the pillars.

The Rice team discovered through computer simulations that removing atoms from the graphene base would force a cone to form between the graphene and the nanotube. The geometric properties of the graphene-to-cone and cone-to-nanotube transitions require the same total number of heptagons, but they are more sparsely spaced and leave a clear path of hexagons available for heat to run up the chimney.

The researchers tested phonon conduction through simulations of free-standing nanotubes, pillared graphene and nano-chimneys with a cone radius of either 20 or 40 angstroms. The pillared graphene was 20% less conductive than plain nanotubes. The 20-angstrom nano-chimneys were just as conductive as plain nanotubes, while 40-angstrom cones were 20% better than the nanotubes.

The tunability of such structures is virtually limitless, stemming from the vast combinatorial possibilities of arranging the elementary modules, said the researchers. The actual challenge is to find the most useful structures given a vast number of possibilities and then make them in the lab reliably. In the present case, the fine-tuning parameters could be cone shapes and radii, nanotube spacing, lengths and diameters. Interestingly, the nano-chimneys also act like thermal diodes, with heat flowing faster in one direction than the other.