Graphene Foam: Introduction and News

What is a foam?

A foam is a substance in which gas is trapped in a liquid or a solid in pockets. There are many types of foams - for example, those used by firefighters (mostly to combat burning oils). A bread is also, at least formally, a type of foam.

Graphene Foams

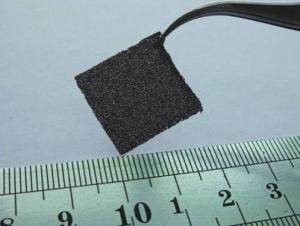

Graphene foams are usually made by growing graphene using a CVD process on a 3D metal foam (structure). The metal is then removed which leaves the graphene 3D foam.

A graphene foam is strong and conductive and useful for many applications - sensors, purification/absorption materials - and more.

Graphene foams are somewhat similar to graphene aerogels, in which the liquid part of the gel is replaced by a gas (usually air).

Graphene foams are now available commercially, contact us for details.

Researchers develop graphene-based battery-free lactic acid sensor

Scientists at the University of Bath, working in collaboration with Integrated Graphene, have created a new type of chemosensor (demonstrated for lactic acid sensing) which functions with electricity but without the need for reference electrodes or battery power. The new design potentially offers lower cost, better shelf-life, and ease of miniaturization compared to enzyme-based sensors. This could open up the possibility for an easy-to-use sensor to be used in remote locations, such as an athletics track, without the need for electricity-powered sensing equipment.

The sensor was able to detect lactic acid, a by-product generated by the body when it metabolizes carbohydrates or glucose for fuel, for example, during exercise. High levels of lactic acid are linked with higher risks of falling unconscious or into a coma and major organ failure.

New GIANCE project focuses on graphene-based solutions for environmental challenges

The GIANCE research project officially commenced on October 1st, marking a step toward addressing environmental challenges with innovative solutions.

GIANCE is an ambitious initiative that seeks to establish a holistic, integrated and industry-driven platform with a clear focus on improving sustainable materials and their real-world applications. This project is dedicated to designing, developing and scaling up the next generation of cost-effective, sustainable, lightweight and recyclable graphene and related materials (GRM)-based multifunctional composites, coatings, foams and membranes (GRM-bM).

Graphite One awarded $4.7 million government contract for graphite and graphene foam fire suppressant

Graphite One, a mining company planning a complete domestic U.S. supply chain for advanced graphite materials, has announced that it has received a US$4.7 million contract from the U.S. Department of Defense's Defense Logistics Agency ("DLA") to develop a graphite and graphene-based foam fire suppressant as an alternative to incumbent PFAS fire-suppressant materials, as required by U.S. law.

"Graphite One is pleased to begin work on this Defense Logistics Agency project, which responds to the legally-mandated requirement to develop a new alternative to long-standing foam fire suppressants which are known to have toxic impacts on human health and the environment," said Anthony Huston, President and CEO of Graphite One. "This DLA contract underscores the importance of graphite for innovative technology applications beyond the renewable energy markets – an important part of Graphite One's advanced graphite materials strategy."

Researchers use graphene foam to create triboelectric nanogenerators for energy systems and autonomous sensors

Researchers from the University of the West of Scotland (UWS), in collaboration with Integrated Graphene, have examined the potential of three-dimensional graphene (3DG) foam (Gii) as an active layer in triboelectric nanogenerators (TENGs) and as an energy harvesting power source for autonomous sensors.

The research showed that the force of a human footprint on a pressure-sensitive mat equipped with Gii-TENG sensors can produce enough energy to anonymously keep track of people entering or leaving a room.

Purdue team develops graphene-based tunable thermal regulators for batteries and electronic devices

Researchers from Purdue University have developed patent-pending, solid-state, continuously tunable thermal devices based on compressible graphene foam composites. The devices can dissipate heat, insulate against cold and function across a wide range of temperatures.

The devices have the potential to improve battery safety and performance in electronic devices and systems like battery thermal management, space conditioning, vehicle thermal comfort and thermal energy storage.

Researchers develop graphene-enhanced foam with medical and environmental applications

Researchers at the University of Georgia have developed a new graphene-enhanced foam material that could significantly reduce health care-related infections caused by implanted medical devices, as well as drastically improve cleanup efforts following environmental disasters, such as oil spills.

The 3D foam is water repellent and exhibits antimicrobial and oil-water separation properties. Its versatility and relatively inexpensive production costs could make it a valuable resource for clinicians and those specializing in environmental remediation.

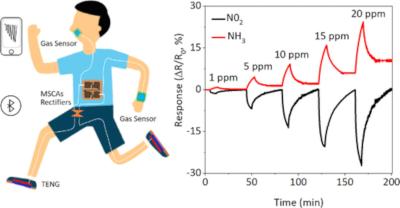

Researchers use graphene foam to develop standalone sensors that use movement to monitor health and environment

A Penn State-led international collaboration has developed a self-powered, standalone sensor system capable of monitoring gas molecules in the environment or in human breath. The system combines nanogenerators with micro-supercapacitors to harvest and story energy generated by human movement.

The researchers' tech should cost up to just a few dollars for materials and uses widely available equipment. The development is the culmination of years of work led by corresponding author Huanyu “Larry” Cheng, James L. Henderson Jr. Memorial Associate Professor of Engineering Science and Mechanics at Penn State.

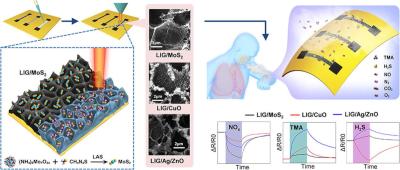

Researchers develop improved method for producing graphene-based gas sensors

Researchers from Penn State and University of Electronic Science and Technology of China recently enhanced their gas sensor manufacturing process through an in situ laser-assisted manufacturing approach, improving on their previous method of drop casting (dropping materials one by one onto a substrate using a pipette.

Flexible gas sensors can be used as medical devices to identify health conditions by detecting oxygen or carbon dioxide levels in the breath or sweat. They are also useful for monitoring air quality in indoor or outdoor environments by detecting gas, biomolecules and chemicals.

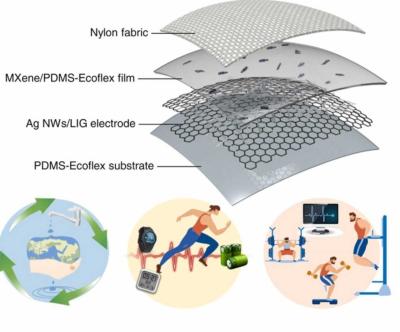

Researchers combine graphene foam and MXenes to create creates high-performance, stretchy nanogenerators

Researchers from China's Hebei University of Technology and The Pennsylvania State University in the U.S have combined MXenes and laser-induced graphene foam nanocomposite to improve the design and performance of triboelectric nanogenerators (TENGs) - power sources that can be used for various flexible electronic devices and wearables.

The popularity of wearable electronics has induced demand for their parts, including power sources such as TENGs. Such power sources must be both stretchy and high-performance, holding up under various deformation conditions over hours of use. The researchers created a material system that enables a TENG to be stretchy and able to perform on dynamic surfaces, such as the human skin or the leaf of a plant.

Researchers develop sensors based on graphene foam for better prosthetics and robotics

Researchers from Integrated Graphene and the University of the West of Scotland (UWS) have reported a project to develop graphene-enhanced pressure sensors that provide enhanced capabilities to robots, helping improve their motor skills and dexterity. The project was supported by the Scottish Research Partnership in Engineering (SRPe) and the National Manufacturing Institute for Scotland (NMIS) Industry Doctorate Program in Advanced Manufacturing.

Professor Des Gibson, Director of the Institute of Thin Films, Sensors and Imaging at UWS and project principal investigator, said: Over recent years the advancements in the robotics industry have been remarkable, however, due to a lack of sensory capabilities, robotic systems often fail to execute certain tasks easily. For robots to reach their full potential, accurate pressure sensors, capable of providing greater tactile ability, are required. Our collaboration with Integrated Graphene Ltd, has led to the development of advanced pressure sensor technology, which could help transform robotic systems.

Pagination

- Page 1

- Next page