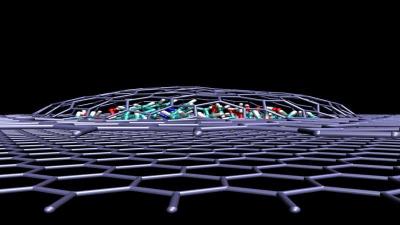

Researchers at Manchester University have shown that a graphene hydraulic ‘nano-press’ is capable of creating new two-dimensional materials by exerting extreme pressure on compounds sealed between layers of graphene. This new use of graphene could prove to be a novel way of creating versatile 2D materials which have unique properties and benefits for a wide range of applications.

The graphene nano-press is made possible due to graphene's unique properties. As is stronger than diamond, the extreme amount of pressure can be exerted on trapped molecules without breaking the graphene layers. The two stacked layers also create a self-sealing envelope around the trapped molecules to contain them. The researchers say that the molecules that are trapped between two layers of graphene experience pressures equivalent of 10,000 times the air pressure in a bicycle tyre; This acts as a nano scale pressure cooker which works at room temperature.

2D crystals of copper oxide, magnesium oxide and calcium oxide were produced using this new technique, at room temperature, which was previously thought to be impossible. Conversion of salt solutions such as copper sulphate, or magnesium chloride usually requires exposure to intense heat and pressure to create these reactions. This new method incurs the same results at room temperature via the pressure created in a one nanometre enclosure between two graphene layers.

According to the team, the observed effects are not limited to graphene enclosures and other 2D crystals can be used, too. Current research within the 2D materials field focuses on fabricating heterostructures made by layering different atomically thin materials and studying various heterostructure devices, for example, nano-sized LEDs. This new research also allows scientists to understand the effect of trapped molecules within new heterostructure devices which could help or disrupt their work.