What is a solar panel?

Solar panel electricity systems, also known as solar photovoltaics (PV), capture the sunâs energy (photons) and convert it into electricity. PV cells are made from layers of semiconducting material, and produce an electric field across the layers when exposed to sunlight. When light reaches the cell, some of it is absorbed into the semiconducting material and causes electrons to break loose and flow. This flow of electrons is an electric current, that can be drawn out and used for powering outside devices. This current, along with the cellâs voltage (a result of built-in electric fields), define the power that the solar cell is capable of producing. It is worth mentioning that a PV cell can produce electricity without direct sunlight, but more sunshine equals more electricity.

A module, or panel, is a group of cells connected electrically and packaged together. several panels can also form an array, which can provide more electricity and be used for powering larger instruments and devices.

Different kinds of Solar cells

Solar cells are roughly divided into three categories: Monocrystalline, Polycrystalline and Thin Film. Most of the worldâs PVs are based on a variation of silicon. The purity of the silicon, or the more perfectly aligned silicon molecules are, affects how good it will be at converting solar energy. Monocrystalline solar cells (Mono-Si, or single-crystal-Si) go through a process of cutting cylindrical ingots to make silicon wafers, which gives the panels their characteristic look. They have external even coloring that suggests high-purity silicon, thus having the highest efficiency rates (typically 15-20%). They are also space efficient (their efficiency allows them to be small) and live longer than other kinds of solar panels. Alas, they are more expensive than other kinds and tend to be damaged by external dirt or snow.

Polycrystalline silicon (p-Si or mc-Si) solar cells do not go through the abovementioned process, and so are simpler and cost less than Monocrystalline ones. Their typical efficiency is 13-16%, due to lower silicon purity. They are also bigger and take up more space.

Thin-Film solar cells (TFSC), are made by depositing one or several thin layers of photovoltaic material onto a substrate. Different types of TFSCs are categorized by which photovoltaic material is deposited onto the substrate: Amorphous silicon (a-Si), cadmium telluride (CdTe), copper indium gallium selenide (CIS/CIGS), polymer solar panels and organic photovoltaic cells (OPC). Thin-film modules have reached efficiencies of 7-13%. Their mass production is simple, they can be made flexible and are potentially cheaper to manufacture than crystalline-based solar cells. They do, however, take up a lot of space (hampering their use in residential applications) and tend to degrade faster than crystalline solar panels.

Solar power advantages and disadvantages

Solar power is free and infinite, and solar energy use indeed has major advantages. It is an eco-friendly, sustainable way of energy production. Solar energy systems today are also much cheaper than they were 20 years ago, and save money in electricity expenses. In addition, it is a much environmentally cleaner form of energy production that helps reduce global warming and coal pollution. It does not waste water like coal and nuclear power plants and is also considered to be a form of energy that is much safer for use.

Although solar power production is widely considered to be a positive thing, some downsides require mentioning. The initial cost of purchasing and installing solar panels can be substantial, despite widespread government subsidy programs and tax initiatives. Sun exposure is critical and so location plays a significant role in the generation of electricity. Areas that are cloudy or foggy for long periods of time will produce much less electricity. Other commonly argues disadvantages regard insufficiency of produced electricity and reliability issues.

Solar power applications

Common solar energy applications include various residential uses such as solar lighting, heating and ventilation systems. Many small appliances utilize solar energy for operation, like calculators, scales, toys and more. Agriculture and horticulture also employ solar energy for the operation of different aids like water pumps and crop drying machines. The field of transportation has been interested in solar powered vehicles for many years, including cars, planes and boats that are vigorously researched and developed. Solar energy also has various industrial applications, ranging from powering remote locations as well as space and satellite systems, to powering transportation signals, lighthouses, offshore navigation systems and many more.

Solar technologies are vigorously researched, aiming to lower costs and improve existing products as well as integrate PV systems in innovative products like PV-powered curtains, clothes and laptop cases.

Graphene and solar panels

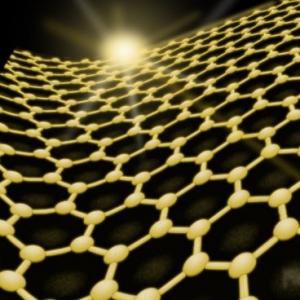

Graphene is made of a single layer of carbon atoms that are bonded together in a repeating pattern of hexagons. It is a 2 dimensional material with amazing characteristics, which grant it the title âwonder materialâ. It is extremely strong and almost entirely transparent and also astonishingly conductive and flexible. Graphene is made of carbon, which is abundant, and can be a relatively inexpensive material. Graphene has a seemingly endless potential for improving existing products as well as inspiring new ones.

Solar cells require materials that are conductive and allow light to get through, thus benefiting from graphene's superb conductivity and transparency. Graphene is indeed a great conductor, but it is not very good at collecting the electrical current produced inside the solar cell. Hence, researchers are looking for appropriate ways to modify graphene for this purpose. Graphene Oxide (GO), for example, is less conductive but more transparent and a better charge collector which can be useful for solar panels.

The conductive Indium Tin Oxide (ITO) is used with a non-conductive glass layer as the transparent electrodes in most organic solar panels to achieve these goals, but ITO is rare, brittle and makes solar panels expensive. Many researches focus on graphene as a replacement for ITO in transparent electrodes of OPVs. Others search for ways of utilizing graphene in improving overall performance of photovoltaic devices, mainly OPVs, as well as in electrodes, active layers, interfacial layers and electron acceptors.

Commercialization efforts

While graphene-based solar cells are not currently commercially available, some efforts are bearing fruit in regards to the use of graphene in auxiliary aspects of PV. One such example is ZNShine Solar's G12 evolution era series - comprised of a 12-busbar graphene module, 5-busbar graphene module and double-glass graphene module. According to reports, the application of ZS's graphene film layer increases light transmission performance of the glass itself. In addition, Znshine Solar's modules are self-cleaning. In July 2018, ZNShine Solar won the bid to provide 37.5MW of PV modules to Bharat Heavy Electricals Limited (BHEL), India's largest power generation equipment manufacturer. According to the contract, 10% of the shipment will be graphene-coated solar panels. In June 2019, Znshine Solar announced signing a 100MW graphene-enhanced solar module supply agreement with UAE's Etihad Energy services.

Further reading

The latest graphene solar news:

Proton transport in graphene may lead to renewable energy production

Researchers at The University of Manchester have found a new and exciting physical effect in graphene membranes that could be used in devices to artificially mimic photosynthesis.

The new findings demonstrated an increase in the rate at which the material conducts protons when it is simply illuminated with sunlight. The 'photo-proton' effect, as it has been named, could be utilized to design devices able to directly harvest solar energy to produce hydrogen gas, a promising green fuel. It might also be of interest for other applications, such as light-induced water splitting, photo-catalysis and for making new types of highly efficient photodetectors.

On Nanotech Engineering's 92% efficiency graphene-CNTs solar panel claim

In early October 2017 we posted about Nanotech Engineering's novel graphene-enhanced solar panel, a post that raised many eyebrows. Nanotech says that their graphene panel reaches a 92% efficiency (compared to around 20% for large commercial silicon-based PV panels), and the cost per Watt of their panel will be 0.55 cents (compared to a US average of $3.26 for silicon PV panels).

Graphene-CNT junctions (source: Rice University)

Our post quoted Nanotech's PR, stating that Jeffrey Grossman, Professor of Engineering at MIT verified the technology and said that Pound for pound, the new solar cells produce up to 1,000 times more power than conventional photovoltaics.

Paragraf announces collaboration with Verditek to develop graphene-based solar panels

Paragraf, a Cambridge-based graphene technology developer, has announced a joint development project targeting new solar technology with Verditek, a clean technology company. The objective is to harness the potential advantages of graphene to improve the output of solar power generation over state of the art cells and panels.

Paragraf, a Cambridge-based graphene technology developer, has announced a joint development project targeting new solar technology with Verditek, a clean technology company. The objective is to harness the potential advantages of graphene to improve the output of solar power generation over state of the art cells and panels.

Paragraf’s proprietary manufacturing process of large scale, high quality graphene will be used for integration with Verditek's solar technology. The program will investigate, develop and verify the application of graphene to solar devices, imparting the advanced electrical and mechanical properties of graphene to solar cells to realize a new generation of highly robust, ultra-light weight panels that will potentially revolutionize the photovoltaic market.

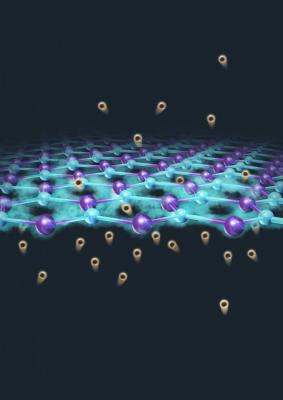

Graphene to increase efficiency of perovskite solar cells

Researchers from Italy’s University of Florence have found that graphene oxide could significantly improve the efficiency of perovskite solar cells. The researchers have shown how the introduction of graphene and graphene oxide doped with lithium atoms (GO-Li) into a perovskite-based cell may increase its conversion efficiency, as both the carrier recombination dynamics and the defect density of the perovskite are considerably improved.

The scientists used graphene doped mesoporous TiO2 (G+mTiO2) with the addition of a lithium-neutralized graphene oxide (GO-Li) interlayer as ETL. They found that the carrier collection efficiency is increased by about a factor two with respect to standard mTiO2.

Graphene Flagship interim results described as "exceptional"

The European Commission has released an interim review report of the Graphene Flagship project's first year following the two-and-half-year ramp-up phase. The Graphene Flagship was concluded to have achieved most of its objectives and milestones and delivered exceptional results with significant immediate or potential impact. The Graphene Flagship is further commended for focusing its work towards a more industrially oriented initiative with a higher Technology Readiness Level.

The report mentioned several significant results close to commercial exploitation, including work with Airbus to produce aircraft parts made of graphene composites, a motorcycle helmet with a graphene coating, a new viscoelastic graphene-polymer sensor material, perovskite photovoltaic cells with improved stability and a demonstration of tuneable ion sieving using GO membrane for water desalination.

Nanotech Engineering's graphene-enhanced solar panel gains MIT's approval

Update: NanoTech Engineering's panel was not in fact verified by MIT. Read our update on nanotech's graphene solar panel here.

Nanotech Engineering announced that MIT (Massachusetts Institute of Technology) has verified the technology of its new Nanopanel, a solar panel that is declared as 92% efficient (as opposed to around 20% for traditional large panels).

Nanotech Engineering announced that MIT (Massachusetts Institute of Technology) has verified the technology of its new Nanopanel, a solar panel that is declared as 92% efficient (as opposed to around 20% for traditional large panels).

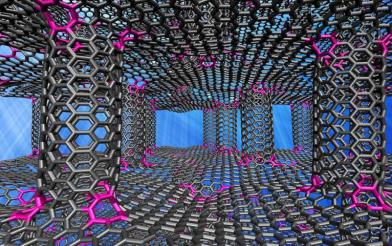

Nanotech Engineering's Nanopanel is described as a solar panel with layers of Graphene as the base, a carbon nanotube forest on top with a mineral solution that can come in any color to match the home. The panel is slightly thicker and wider than a FedEx envelope, yet stronger than steel, flexible, lightweight, flexible and about half the cost of traditional panels, said Nanotech.

Graphene-enhanced fluid improves solar collectors' efficiency

Researchers at the University of Lisbon's Centro de QuÃmica Estrutural have discovered that the addition of graphene to the working fluid of solar collectors helps to regain some of its lost efficiency. Solar thermal collectors are seen as a simple and inexpensive way to make use of solar energy. Pure water is an efficient heat-transfer fluid, but it must be mixed with antifreeze to prevent damage to pipes during freezing conditions, and this lowers its performance.

The properties of an ideal heat-transfer fluid in a solar collector include a high thermal capacity and a freezing point outside of the temperature range likely to be encountered. Unfortunately, in the case of water, satisfying the latter requirement means compromising on the former, as mixing water with antifreeze makes it a less effective carrier of heat.

NSF grant to fund development of inkjet-printed graphene-based water quality sensors

The National Science Foundation recently awarded University of Wisconsin-Milwaukee scientists $1.5 million to perfect a method of mass-producing graphene-based small water sensors using inkjet printing. The goal is to determine whether the process can be customized in order to scale up production and in a more economic way than traditional manufacturing methods.

The graphene-based sensors, developed at UWM, reportedly outperform current technologies in accuracy, sensitivity and sensing speed. Their performance and size make them useful for continuously monitoring drinking water for miniscule traces of contaminants like lead.

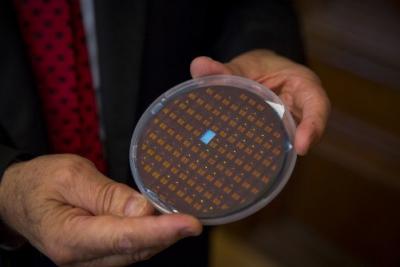

Grolltex announces new CVD graphene facility

Grolltex, a U.S-based advanced materials and equipment company, recently announced a large-capacity commercial lab for production of high quality CVD graphene. Grolltex states that it is now manufacturing the material in its new class 1000 clean room, producing both raw graphene as well as products made from the material, like sensors, perovskite solar cells, display materials and X-ray windows for use in spacecraft.

Grolltex, a U.S-based advanced materials and equipment company, recently announced a large-capacity commercial lab for production of high quality CVD graphene. Grolltex states that it is now manufacturing the material in its new class 1000 clean room, producing both raw graphene as well as products made from the material, like sensors, perovskite solar cells, display materials and X-ray windows for use in spacecraft.

The new Grolltex graphene facility is said to be capable of producing large high-quality sheets of graphene for commercial sale. The Company is said to have a patented methodology to manufacture the material in a novel way that yields lower-cost materials of high quality. Grolltex leverages graphene research and patents developed at nearby University of California, San Diego.

MIT team creates flexible, transparent solar cells with graphene electrodes

Researchers at the Massachusetts Institute of Technology (MIT) have developed flexible and transparent graphene-based solar cells, which can be mounted on various surfaces ranging from glass to plastic to paper and tape. The graphene devices exhibited optical transmittance of 61% across the whole visible regime and up to 69% at 550 nanometers. The power conversion efficiency of the graphene solar cells ranged from 2.8% to 4.1%.

A common challenge in making transparent solar cells with graphene is getting the two electrodes to stick together and to the substrate, as well as ensuring that electrons only flow out of one of the graphene layers. Using heat or glue can damage the material and reduce its conductivity, so the MIT team developed a new technique to tackle this issue. Rather than applying an adhesive between the graphene and the substrate, they sprayed a thin layer of ethylene-vinyl acetate (EVA) over the top, sticking them together like tape instead of glue.

Pagination

- Previous page

- Page 5

- Next page