Researchers at the Department of Energy’s Lawrence Berkeley National Laboratory have developed a mix of metal nanocrystals wrapped in graphene that may open the door to the creation of a new type of fuel cell by enabling enhanced hydrogen storage properties.

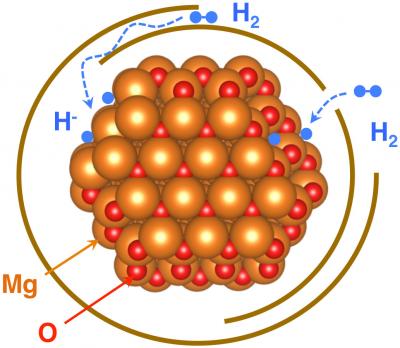

ultrathin oxide layer (oxygen atoms shown in red) coating graphene-wrapped magnesium nanoparticles (orange) still allows in hydrogen atoms (blue) for hydrogen storage applications

ultrathin oxide layer (oxygen atoms shown in red) coating graphene-wrapped magnesium nanoparticles (orange) still allows in hydrogen atoms (blue) for hydrogen storage applications

The team studied how graphene can be used as both selective shielding, as well as a performance increasing factor in terms of hydrogen storage. The study drew upon a range of Lab expertise and capabilities to synthesize and coat the magnesium crystals, which measure only 3-4 nanometers (billionths of a meter) across; study their nanoscale chemical composition with X-rays; and develop computer simulations and supporting theories to better understand how the crystals and their carbon coating function together.

The study's lead author stated Most people would suspect that the oxide layer is bad news for hydrogen storage, which it turns out may not be true in this case. Without this oxide layer, the reduced graphene oxide would have a fairly weak interaction with the magnesium, but with the oxide layer the carbon-magnesium binding seems to be stronger. That’s a benefit that ultimately enhances the protection provided by the carbon coating. There doesn’t seem to be any downside.

The researchers noted that the current generation of hydrogen-fueled vehicles power their fuel cell engines using compressed hydrogen gas. This requires bulky, heavy cylindrical tanks that limit the driving efficiency of such cars, and the nanocrystals offer one possibility for eliminating these bulky tanks by storing hydrogen within other materials.

The models that were developed to explain the experimental data suggest that the oxidation layer that forms around the crystals is atomically thin and is stable over time, suggesting that the oxidation does not progress.

While many simulations are based around very pure materials with clean surfaces, the team said, in this case the simulations were intended to be more representative of the real-world imperfections of the nanocrystals. A next step, in both experiments and simulations, is to use materials that are more ideal for real-world hydrogen storage applications, such as complex metal hydrides (hydrogen-metal compounds) that would also be wrapped in a protective sheet of graphene. By going to complex metal hydrides, you get intrinsically higher hydrogen storage capacity and our goal is to enable hydrogen uptake and release at reasonable temperatures and pressures, the researchers said.

Some of these complex metal hydride materials are fairly time-consuming to simulate, and the research team plans to use the supercomputers at Berkeley Lab’s National Energy Research Scientific Computing Center (NERSC) for this work.