Bluestone Global Tech (BGT) was founded in 2011 in New York with an aim to produce graphene. The company offers high-quality, fully customizable graphene on several substrates (Quartz, Copper, Silicon and others). BGT's CEO, Dr. Chung Ping Lai, was kind enough to answer a few questions we had about the company's business and technology.

Bluestone Global Tech (BGT) was founded in 2011 in New York with an aim to produce graphene. The company offers high-quality, fully customizable graphene on several substrates (Quartz, Copper, Silicon and others). BGT's CEO, Dr. Chung Ping Lai, was kind enough to answer a few questions we had about the company's business and technology.

Dr. Lai became BGT's CEO in November 2012. Previously he worked with Taiwan's ITRI institute, Veeco, Applied films and other companies. Dr. Lai received his Ph.D. degree from the Department of Ceramics Science and Engineering of Rutgers University in 1992.

Q: Can you tell us about BGT's current production facility? What is your capacity? what kind of processes are being used?

BGT’s current manufacturing facility has a capacity of 20 m2/day and will expand to 200 m2/day in Q3/13. In addition, we will expand to China to be closer to our customer by Q4 of this year.

Currently, we use CVD for our single/multi-layer graphene. We also have graphene oxide and platelet products ready for marketing.

Q: Can you tell us a bit about your customer applications? What kind of products or research is being done using your products?

- We have assisted our customers manufacture touch panels using our graphene.

- We have shipped our graphene anode products for LiB applications.

- We will announce, with our customers, flexible smart film products in about one month.

- A few other applications in consumer electronics and biomedical applications will be announced soon.

Q: When do you think we can see products on the market that use BGT made films?

Touch panel market; in Q3/13.

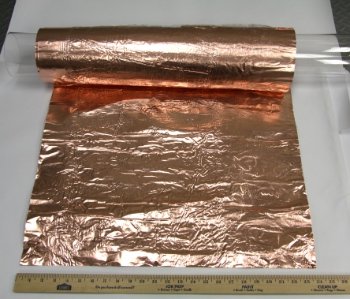

Q: You recently announced the availability of 24" by 300" graphene film on copper. What are the possible applications of this product? Is it possible to remove the copper and get a large graphene sheet from that?

Possible applications include touch panels, smart films, etc.

We have developed the large-area dry transfer method. Using our proprietary transfer methods, we can transfer very large-area graphene onto a wide variety of substrates - without sacrificing copper.

Q: Can you share with us your own forecasts for the graphene market in the next 3-5 years?

We expect graphene to first make application penetration in the touch panel market, as an ITO-replacement. We believe that the penetration rate will be quite a remarkable replacement rate of 5% in 2014.

We expect, by 2015, that graphene-enhanced flexible electronics will really take off and expand quickly into the entire portable electronics domain.

Dr. Lai, thank you for your time and answers. I wish you and BGT the best of luck, and hopefully we'll begin to see the first BGT graphene based products in Q3 2013 indeed!